Guidelines for Wall Thickness in Laser Sintering

A study reveals insights for additively manufacturing reliable walls and avoiding warpage.

Wall thickness is a crucial and fundamental design feature. Laser sintered (LS) parts in particular are exposed to very high temperatures throughout the build, making them vulnerable to warp during the heating and cooling of layers. Thin walls are more likely to warp due to differential shrinkage during the cooling process.

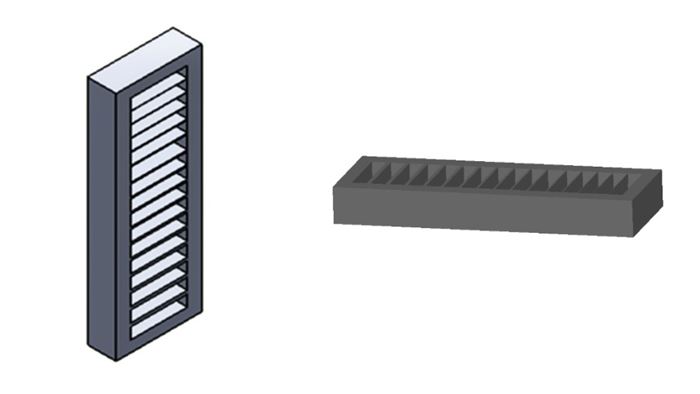

A sponsored study between Stratasys Direct Manufacturing and The University of Texas at Austin was formed to determine design rules for LS that ensure polymer parts made through this process meet accuracy and repeatability requirements. The research team designed a simple part to test 15 varying wall thicknesses, ranging from 0.2 to 3 mm, to determine the thinnest resolvable wall dimensions before degradation. The test piece was built using two orientations in relation to the surface of the build: parallel to the build surface, or “horizontal,” and perpendicular to the build surface, or “vertical,” to test how orientation could affect quality and manufacturing feasibility.

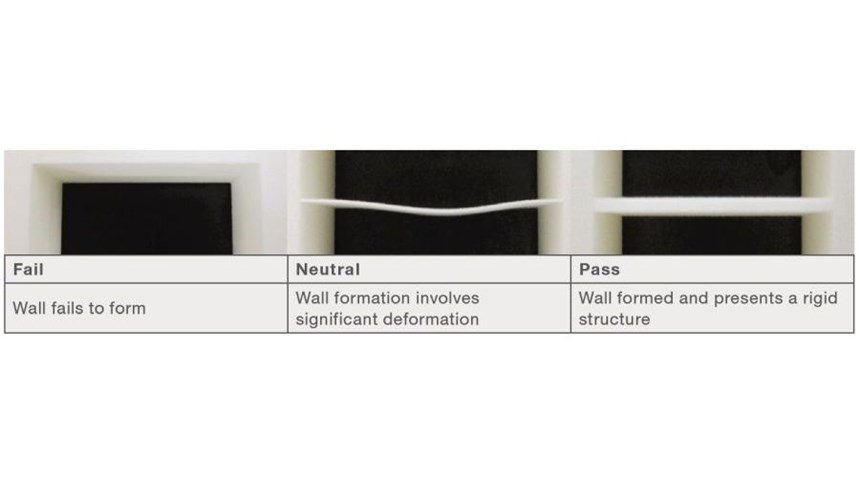

Both vertically and horizontally oriented walls failed reliability standards when they measured 0.5 mm thick or less. Walls built with a vertical orientation with that measurement were simply not able to form, while horizontally oriented walls exhibited considerable warp.

The team then compared wall thicknesses from 1 to 1.6 mm. All wall thicknesses at or above 1 mm were able to fully resolve. Further analysis of the walls within these test pieces found that horizontally built walls have greater accuracy than vertically built walls.

Thicker walls mean more stability and lower chances of warping regardless of orientation, but the resolvability difference between vertical and horizontal orientations comes down to two factors: layer thickness and laser spot size. Layer thickness is 0.1 mm while the laser spot size is 0.47 mm in diameter; the issue arises within these dimensions. The layer thickness is smaller than the laser spot size causing horizontally oriented walls to resolve better. Even with this knowledge, it’s important to keep in mind that generally, horizontally built walls are more susceptible to warp because they take up a larger surface area across the horizontal plane.

Given the test results, the following guidelines are recommended:

- Design walls thicker than 0.6 mm for reliability.

- Orient thin walls to build horizontally rather than vertically

- Be aware of warping when constructing a wall with a thickness less than 0.6 mm.

Related Content

-

How Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

-

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.