Grinding Improves Surface Finish in 3D Printed Inconel, Study Shows

3D printed metal parts typically feature little stock remaining for finishing. Grinding is potentially an effective solution for meeting final tolerances. An abrasive technology provider investigates grinding as a complement to AM.

The increased use of additive manufacturing (AM) in the aerospace and medical markets fosters a growing need to finish the surfaces of additive parts to meet final application requirements. Since the AM process is capable of producing components close to near-net shape, there is often little stock that remains for providing final finish. This benefits the overall manufacturing process by reducing waste, but it also means that subsequent finishing processes have limited room for postprocessing errors and inconsistencies. Postprocessing, therefore, needs to be consistent in achieving part tolerances and surface quality. This article will demonstrate that grinding offers an effective option with additive manufacturing when close tolerances and finer finishes are required. When compared with other traditional material removal processes such as milling and turning, grinding typically offers the best surface quality and surface integrity characteristics. In order to gain more insight into finishing for AM specifically as it might apply to nickel-based superalloy components used in aerospace, engineers at Norton | Saint-Gobain conducted a finish grinding study on Inconel 718 specimens made additively. The engineers were seeking answers to three pertinent questions:

- What is the minimum stock/volume that needs to be ground off an AM component?

- What range of surface finishes can be obtained from grinding an AM component with the latest generation of abrasive grinding wheels?

- What, if any, is the impact on surface residual stresses on an AM component after finish grinding?

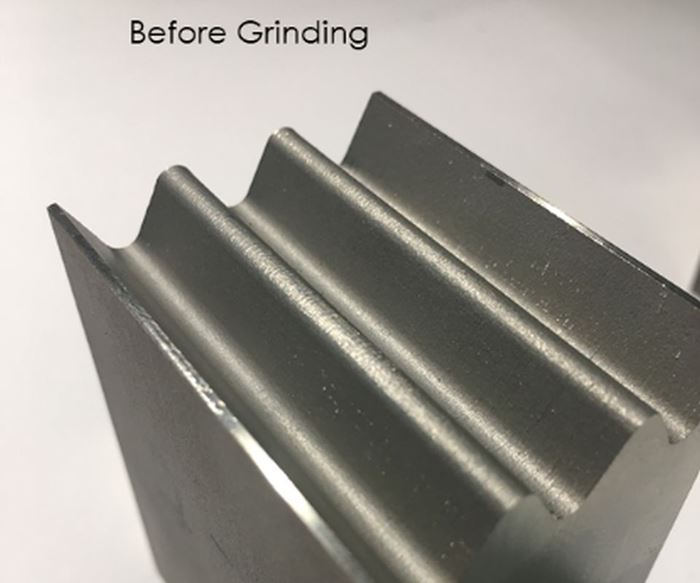

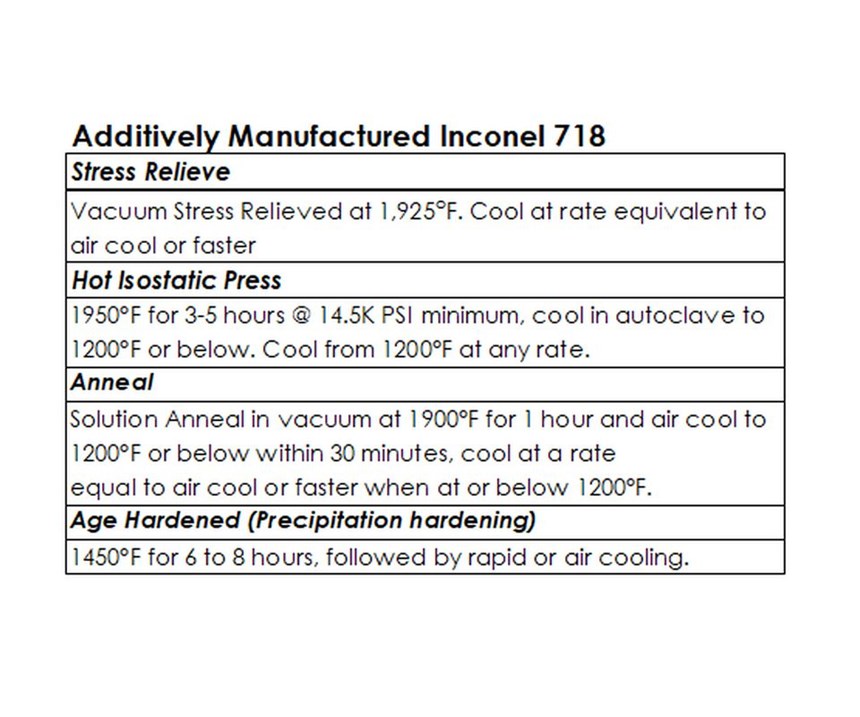

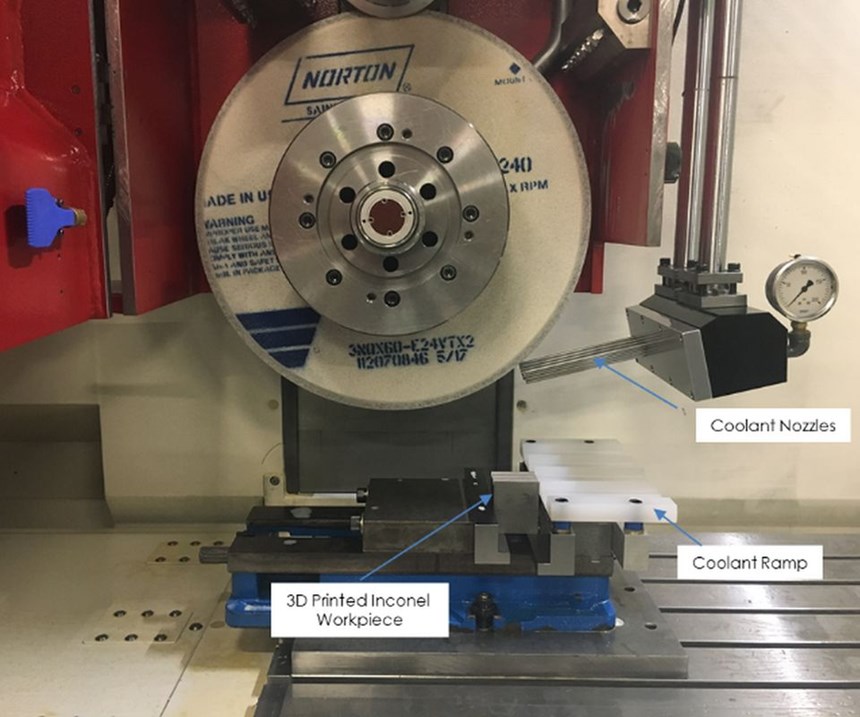

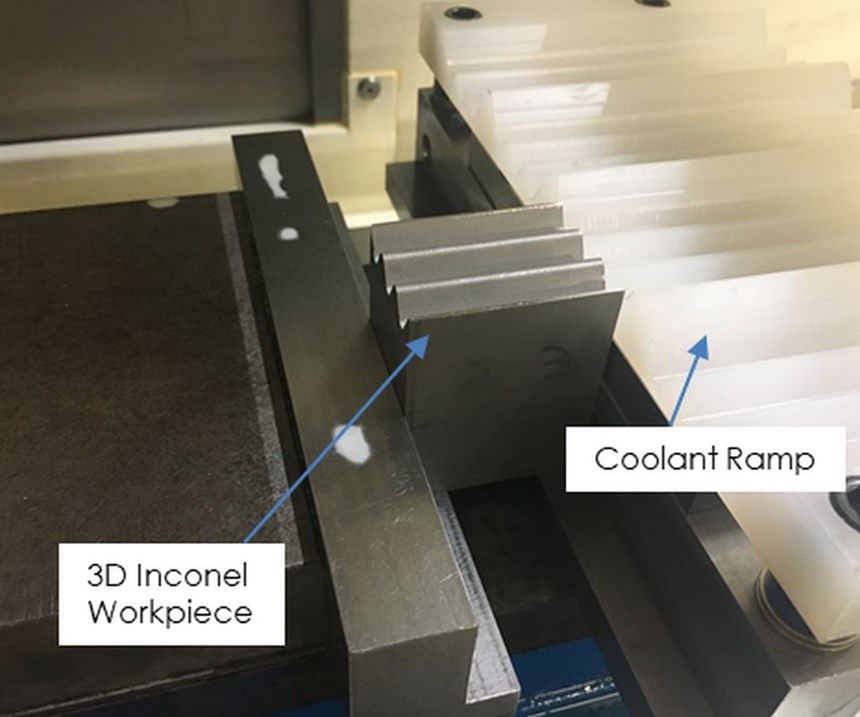

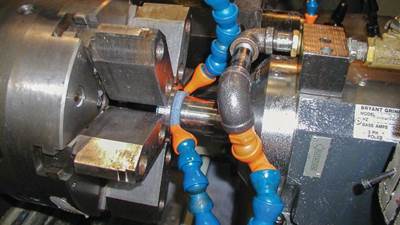

AM IN718 specimens manufactured using the direct metal laser sintering (DMLS) process were obtained from Stratasys Direct Manufacturing. Figure 1 shows an image of the AM test specimen. After AM, these specimens were media blasted and went through stress relief, hot isostatic pressing, solution treatment/anneal and precipitation hardening. Table 1 shows the heat treatment parameters used. The hardness of the specimens measured 40 HRC. The specimens were then ground using a Norton NQX60E24VTX2 grinding wheel on a Magerle MFP-125.50.65 creepfeed grinder located at the Norton | Saint-Gobain Higgins Grinding Technology Center. Figures 2 and 3 show a picture of the test set-up.

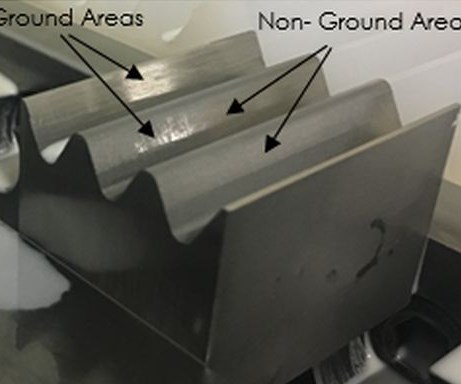

First, several areas were ground at progressively increasing depths of cut to determine the minimum stock that needs to be removed to clean up an additively manufactured surface. After each grind at a specific depth of cut, the surfaces were looked at for the presence of visual imperfections. Figure 4 shows an image of the specimen that is partially cleaned during this sequence of trials. The trial results determined that in order to eliminate any geometrical inconsistencies and surface imperfections related to the AM process, approximately 0.30 - 0.45 mm of stock needs to be removed from the component.

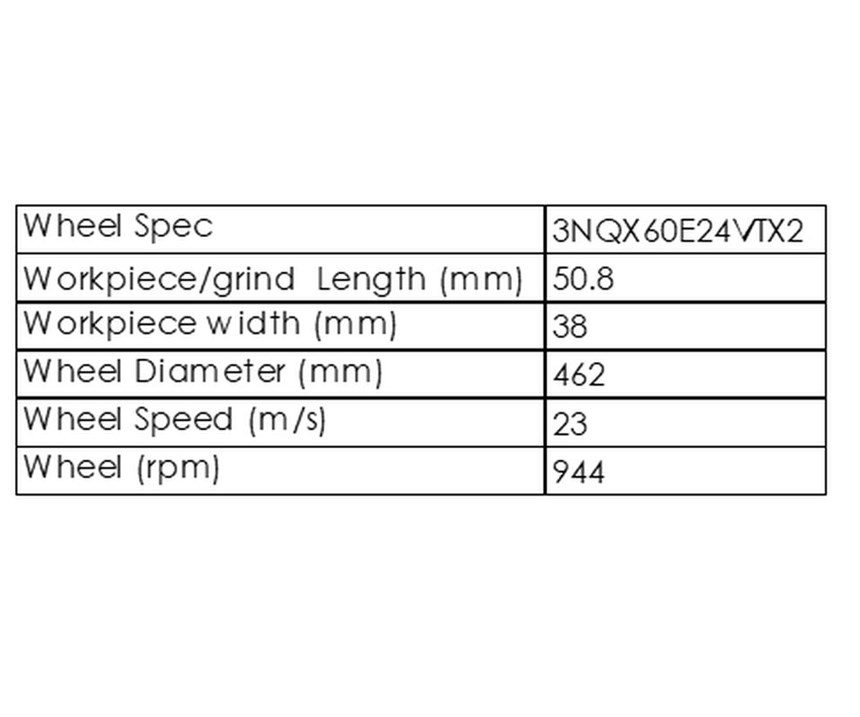

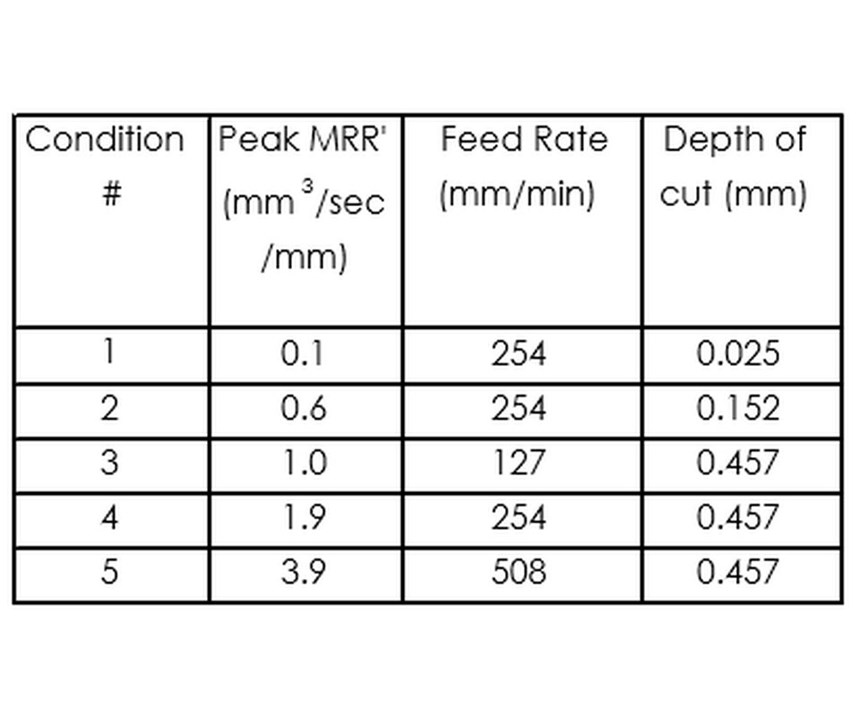

For this test, the grind length was 50.8 mm, and the wheel diameter was 462 mm, operating at 23 m/sec (see Table 2). Tables 2 and 3 document test details and grinding conditions used in the study. A total of five specific material removal rates (MRR’) were tested ranging from 0.1 mm3/sec./mm to 3.9 mm3/sec./mm (see Table 3). The MRR’ was adjusted by altering the feedrate (mm/min.) or the depth of cut (mm). Multiple material removal rates were tested in order to evaluate the effect of low to medium MRR’s on surface finish and grinding power. While nickel-based alloys such as Inconel 718 can be ground at high removal rates using modern engineered abrasives, the MRR’s selected in this study were lower, based on the typical finishing rates used in industrial processes now to finish standard Inconel workpieces. Based on the grinding of standard (non-AM) workpieces, the expected results were that as MRR’ increased, surface finishes (Ra) of ground workpieces would increase or get coarser, as grinding power increased.

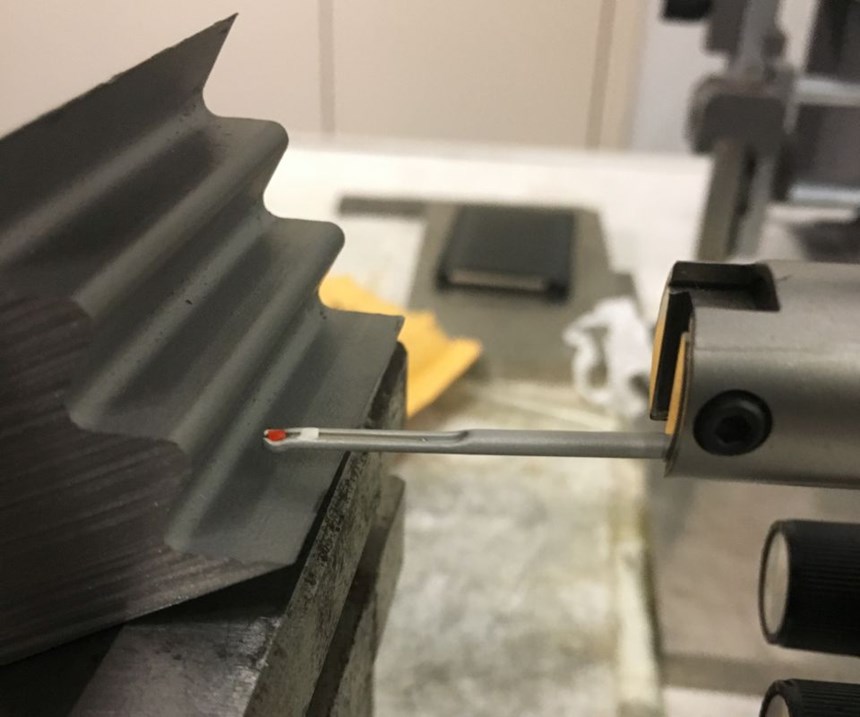

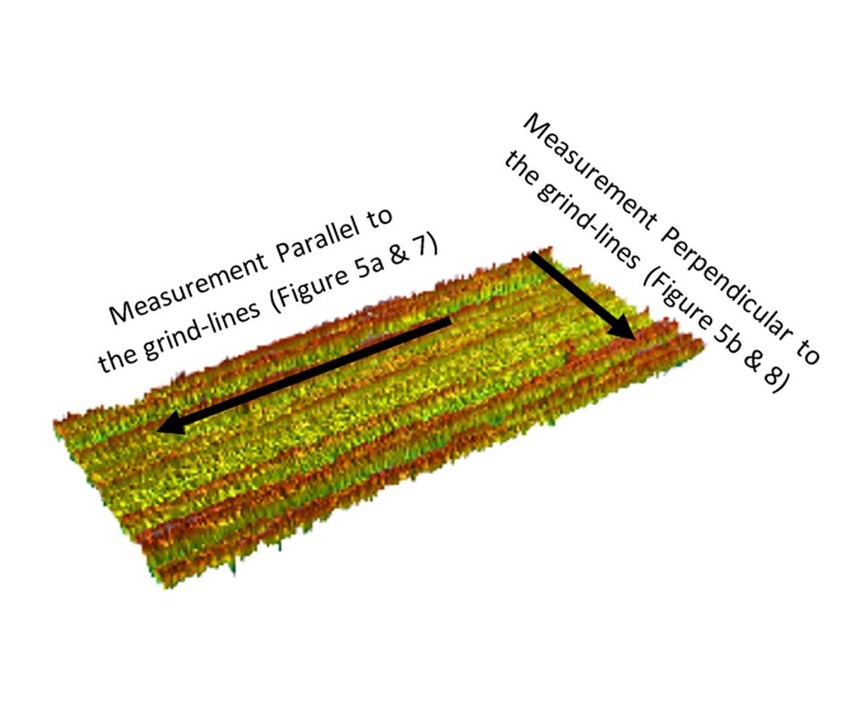

The surface finishes of the workpieces were measured before and after grinding using a Federal Contact profilometer system 5000. Measurements were taken at several locations and in two directions on the workpiece (Figures 5a and 5b). Non-contact profilometer surface measurements were also taken in multiple locations (Figure 6).

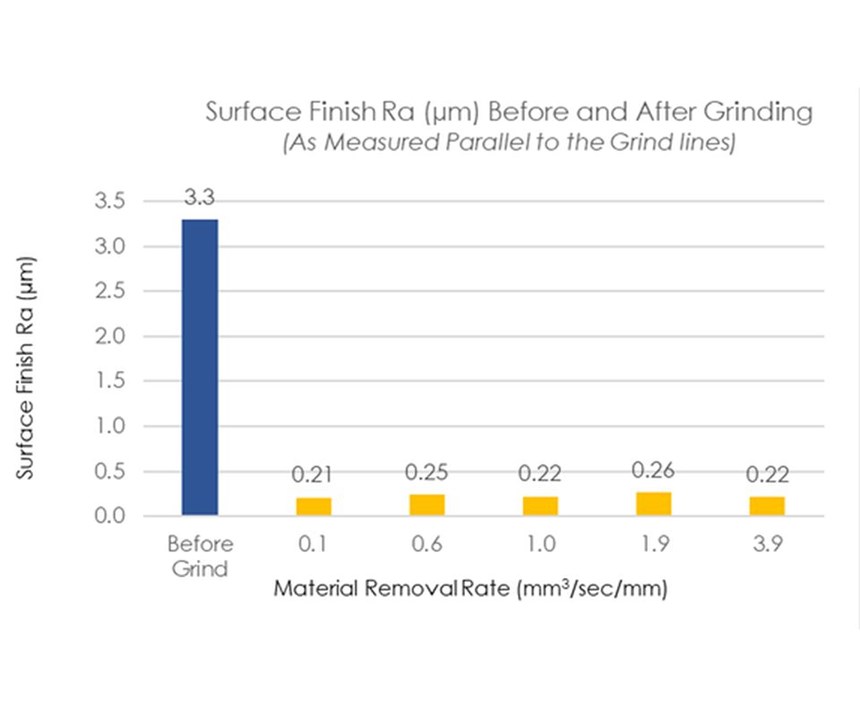

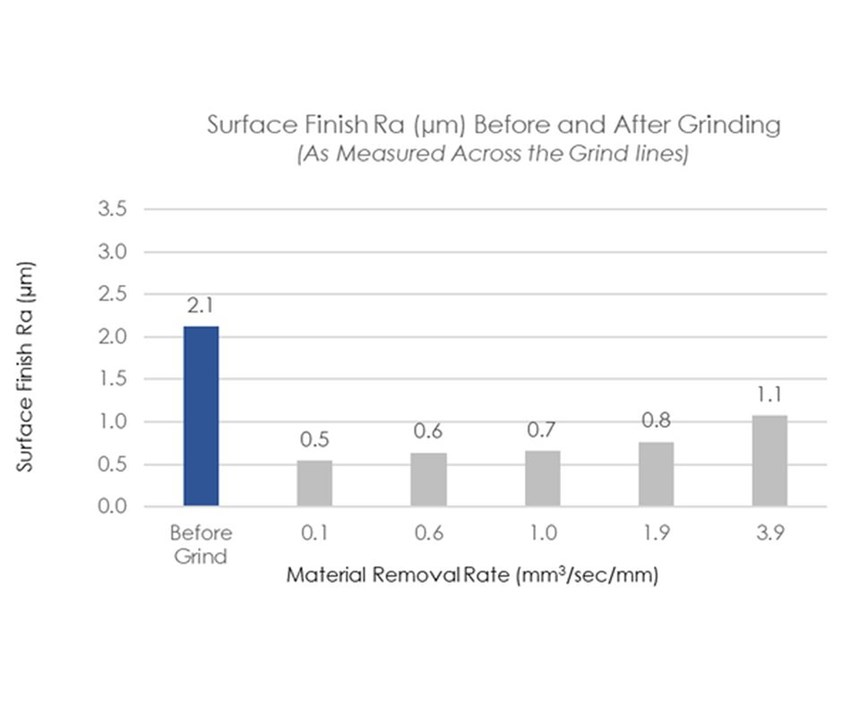

An evaluation of the surface finish on the AM material before grinding found it to be considerably different depending on the direction of measurement (as shown when comparing Figures 7 and 8). When measured lengthwise (Figure 5a), the average finish was 3.3 microns Ra and when measured widthwise (Figure 5b), the average finish was 2.1 microns Ra. This large difference would not typically be observed when measuring a standard, as-cast Inconel 718 material. This appears to be related to the 3D manufacturing method, but the exact reason is unknown at this time.

The conventional method when measuring a ground surface finish, using a contact profilometer, is to take the trace perpendicular to the grind-lines as opposed to measuring parallel to the grind lines. In this study it was decided to measure the surface finish after grinding in both parallel and perpendicular directions to the grind-lines. The after grind results were then compared to the before grind lengthwise and widthwise measurements, as shown in Figure 7 and 8.

It is important to understand that when measuring a ground surface in a perpendicular direction to the grind-lines, the stylus travels over the peaks and valleys of the grind-lines. Whereas when measuring in the parallel direction the stylus moves parallel to the grind-lines never crossing over the peaks and valleys (Figure 6). Therefore, perpendicular measurements taken in this study had significantly higher (coarser) surface finish results as compared to measurements taken in a parallel direction, as would be expected (Figures 7 and 8).

An evaluation of the surface finish on the AM material before grinding versus after grinding found that grinding improved the surface finish significantly. This was true for measurements in both the parallel and perpendicular directions. When measuring in a parallel direction, the average surface finish was 3.3 microns Ra before grinding and 0.21 microns Ra after grinding (Figure 7). When measuring perpendicular to the grind direction the surface finish was an average of 2.1 microns Ra before grinding, and as low as 0.5 microns Ra after grinding (Figure 8).

Additive specimens were also analyzed using a Nanovea 3D surface profilometer, white light chromatic aberration technique, to obtain a visual representation of the surface features. Figure 9 is a 3D surface plot of the AM specimen taken before grinding, in the “as-received” condition, and after grinding. For this test, the AM specimen in the “as-received” condition was media blasted with glass media to take off the high peaks from the surface. The lines that are visible on the surface plot taken after grinding are lay lines from the grinding operation. Grinding wheels with finer abrasive grains or other abrasive products, such as engineered abrasive belts, can be used to reduce the lay lines further and generate a super-finished surface if that is a critical requirement to the component’s performance and quality.

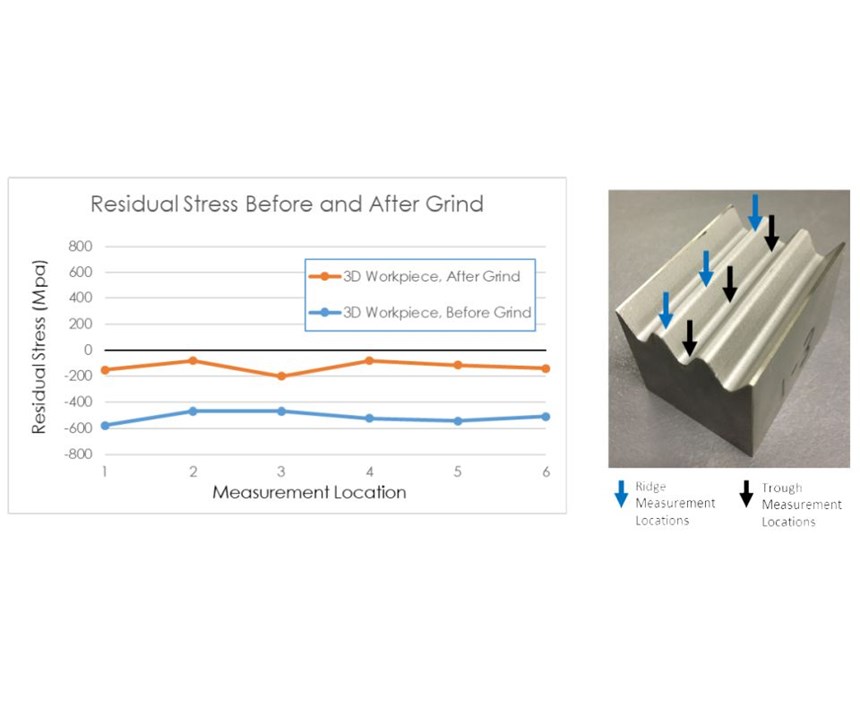

In order to understand the impact of grinding on the overall surface integrity of the AM IN718 specimen, surface residual stresses of the AM specimens were measured using Bruker-AXS D8 Discover microdiffraction equipment in the “as received” condition as well as after grinding. A comparison of the measurements taken in both conditions at six different locations on the same specimen (Figure 10) proves that near-surface residual stresses are negative/compressive in both the “as-received” and “after-grind” condition. This is typical of components after finish grinding, where near-surface residual stresses are found to be compressive in nature, an effect that tends to help fatigue life by retarding surface crack propagation.

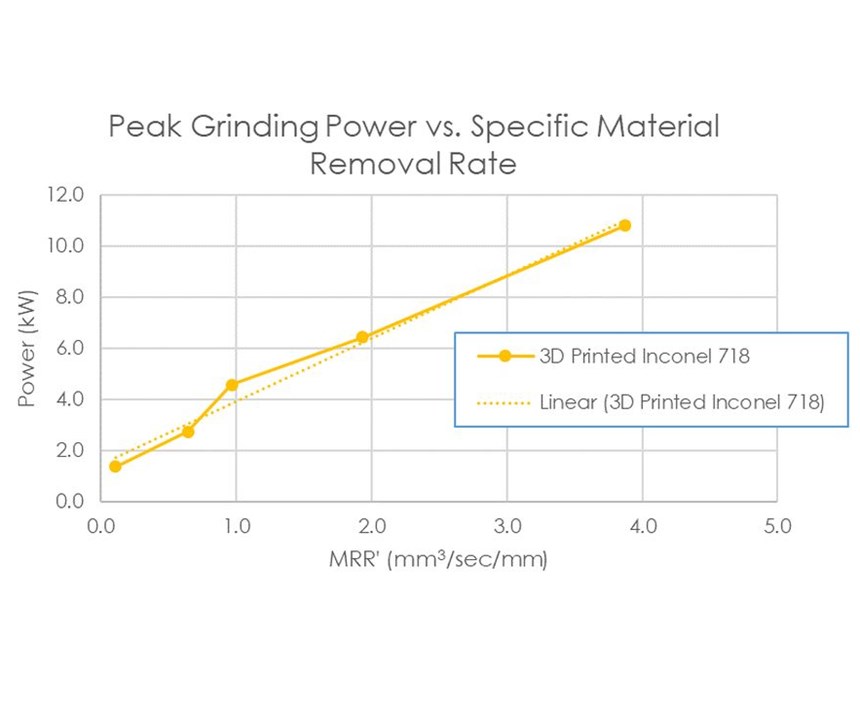

Grinding power was measured for all five material removal rates tested in this study. Figure 11 shows that as the MRR’ is increased, the grinding power also increases. This behavior is typical of most grinding operations. At the lowest rate of 0.1 mm3/sec./mm, the peak power draw during the grind was 1.4 kW. At the highest material removal rate of 3.9 mm3/sec./mm, the grinding power was 10.8 kW.

The results of this study proved that finish grinding of additively manufactured, nickel-based superalloys, such as Inconel 718, can be successfully employed to achieve a reduction in surface roughness of approximately 94 percent when measured parallel to the grind lines and approximately 34 percent when measured perpendicular to the grind lines. Grinding wheels with finer abrasive grains or other abrasive products, such as engineered abrasive belts, can be used to generate a super-finished surface if required. It also showed that approximately 0.30 mm - 0.45 mm of stock needs to be removed from the component to generate improved surface finishes and clean up any geometrical inconsistencies related to the 3D manufacturing process. The minimal stock requirement is critical information for additive manufacturers as they strive to make AM components as close to near-net shape as possible to be cost-effective. Moreover, the residual stress data showed that the surface stresses after grinding were compressive in nature, indicating a beneficial impact on retarding surface crack propagation and thereby extending the fatigue life of manufactured components.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreRead Next

3D Printing with Postprocessing in Mind

3D printing requires different finishing considerations than traditional manufacturing. One expert offers do’s and don’ts for approaching the finishing of additively manufactured parts.

Read MoreAdditive Manufacturing’s Assist to ID Grinding

Additive manufacturing helped Norton/Saint-Gobain achieve better cooling in a grinding application.

Read MoreOptions for Finishing and Postprocessing Metal 3D-Printed Parts

There is a host of technologies available for finishing and postprocessing your AM parts. This column identifies options beyond machining.

Read More