Geometry Toolkits Play Complementary Roles in AM

Integrating data types in modeling and preparing the model for 3D printing are strengths of separate systems.

Share

Read Next

If you’re like most people, at some point today you probably sat down to a table that presented you with a fork, a knife and a spoon.

It’s likely that you did not find this arrangement perplexing or confusing. You knew to grab the spoon when you had a bowl of soup in front of you, to grab a knife when you had a steak in front of you and so on. The utensils were complementary, each performing a different function that made them well suited for certain tasks, and less suited to others.

Manufacturers would do well to bring a similar mindset to geometry toolkits. Particularly as 3D printing increasingly takes its place alongside other part-making processes, the question related to engineering software isn’t “Which geometry toolkit should I buy?” but rather “What type of tasks will the software need to tackle?”

An exploration of two common use cases reveals that the best approach might be for users to have an array of complementary tools—a full set of utensils, if you will—at their disposal, rather than just one. Let’s take a closer look.

Use Case 1: Performing Modeling Operations on Two Types of Data

For 20 years, boundary representation (BREP) has been the dominant way to define models in the manufacturing world—but other types of 3D representation, such as faceted data, are growing in popularity. Much of this growth is driven by an increase in scan data across multiple markets.

Laser scanners are becoming increasing affordable and ubiquitous, capturing scores of information at both a micro and macro level. Meanwhile, in the medical field, biological information is gathered via CT scans, rasterized versions of X-rays and other techniques to create various forms of prosthetics, implants and other devices.

Once all this scan data has been sanitized and turned into triangles, people need a way to bring it together with their BREP geometry and be able to work on it in a single session. Doing this requires a unification of the two datatypes in one environment, something that a tool like Siemens Parasolid provides with the addition of its new set of Convergent Modeling tools.

This convergent modeling environment opens up all kinds of possibilities for working with faceted geometry. Suddenly, you have the ability to perform serious modeling operations on your facet data—everything from Boolean operations, to cuts, sweeps, and blends. Better yet, the models can maintain the topology of BREP geometry when it is brought into the faceted world.

For advanced shape authoring and editing, Parasolid is an appropriate modelling toolkit.

Use Case 2: Preparing Models for 3D Printing

Additive manufacturing has surged in popularity in recent years, making 3D printers an increasingly common output for models. Unfortunately, 3D printing is still a notoriously finicky process: Every file must be completely print ready or the results can be disastrous.

Let’s turn to the medical field for an example. Having a watertight STL file to print is a necessity for producing a dental implant. If the model of the implant has even a tiny hole in it, the printed result will be hollow rather than solid. If this hollow implant is subjected to even a small amount of pressure, it will shatter—which, of course, is not the desired result for something being implanted in someone’s mouth.

Preparing data for 3D printing isn’t just a matter of looking for holes—there’s all manner of other adjustments that need to be made to ensure a truly watertight file. Sometimes your triangles are intersecting one another, which is not printable, so you need to remove those self-intersections. Other times, you have more than two triangles sharing an edge; that’s called a non-manifold triangle, and those need to be removed as well. On it goes with various other nips, tucks and rearrangements.

This is where a tool whose focus is mesh healing and preparation for 3D printing comes in handy. MachineWorks Polygonica provides an example. You can quickly and easily flip triangles in the right direction and remove self-intersecting and non-manifold triangles. You can also prepare files for 3D printing through numerous other tools: simplify mesh to reduce the triangle count by orders of magnitude; merge, offset and hollow meshes; and create a set of parallel 2D slices for output to a 3D printer.

It doesn’t do modeling with BREP data, and it’s not as full featured as Parasolid, but if you need to quickly work with triangles to prepare them for 3D printers, Polygonica is a good tool for the job.

Different Toolkits for Different Uses

As the use cases above illustrate, it’s not a case of one geometry toolkit versus the other. Both toolkits profiled are good for their given use cases—complementary even. This represents the best way to approach geometry toolkits: seeing them as different tools that together can provide a full spectrum of functionality. There’s no need to take an “either/or” approach when “both/and” is a viable option.

About the Author

Gavin Bridgeman

Gavin Bridgeman is chief technical officer at Tech Soft 3D.

Related Content

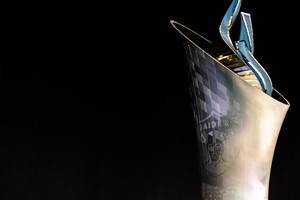

The World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreAdditive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More