Finding the Value Proposition for Additive Manufacturing

Why would anyone want to use additive manufacturing?

Share

Read Next

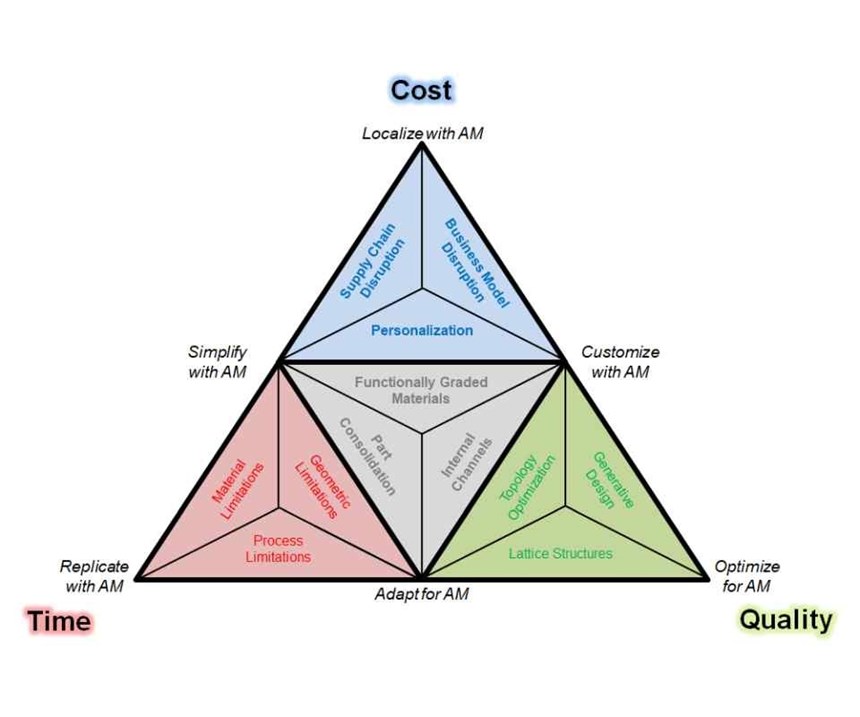

Additive manufacturing (AM) provides design and material freedoms for making parts that are impossible or too expensive to fabricate with traditional manufacturing processes such as milling and casting. Although design for additive manufacturing (DFAM) has its limitations, it also enables new opportunities like lattice structures, conformal cooling channels and more.

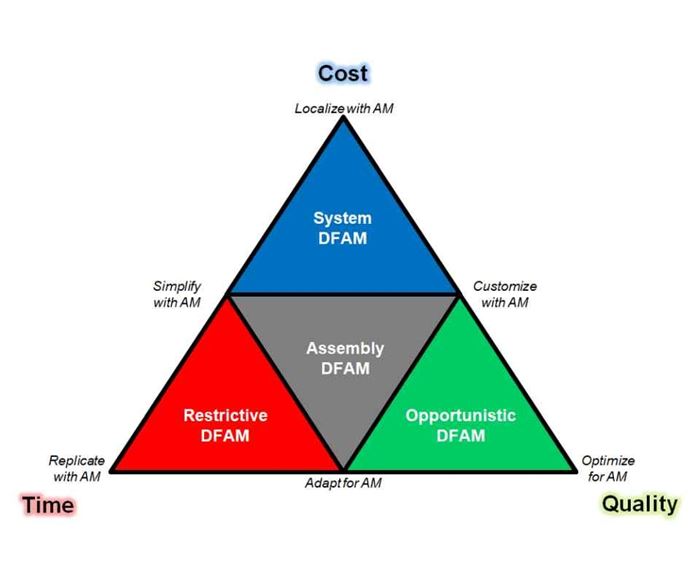

We often think only at the part level for DFAM, but it can be applied at the assembly and system levels as well (see first figure above), and different benefits accrue at the different levels. The many possibilities of AM outweigh the limitations.

“We aren’t going to fly a 3D-printed part just because it’s cool. It has to buy its way onto the engine just like any other part.”

Yet being enamored with these attractive possibilities—the “what” and the “how” of AM—still doesn’t get us to the “why,” the ultimate reason for using AM. It has to deliver on a value proposition. As William Brindley from Pratt & Whitney once told me, “We aren’t going to fly a 3D-printed part just because it’s cool. It has to buy its way onto the engine just like any other part.”

Cost is only one factor that potentially drives this acceptance. Quality and time (speed) are the other two main drivers, and AM can help improve all of these when used effectively. For instance, lattice structures can be used to create lighter-weight components with better strength-to-weight ratios. This improves part quality while reducing the cost of AM by using less material and build time to make the part. This may even enable a material substitution, improving the life and durability of the part. In medical applications such as implants, lattice structures improve osseointegration, which improves bond strength and helps patients recover faster. Over time, this leads to fewer implant revisions, fewer replacements and ultimately fewer surgeries.

Topology optimization also can be used to create lightweight structures for aerospace or space structures. Why is light weight good in these applications? I have seen estimates that saving 1 kilogram of weight on a plane saves $3,000 a year in fuel costs. In space applications, the savings jumps to $10,000 per kilogram of weight saved, or the company can trade the weight savings to haul more payload, making the launch more profitable. Companies also save money because they improve their material-use buy-to-fly ratio, which I have seen as high as 80-to-1 in some cases. Less material is needed to make a topology-optimized component, reducing material costs and build time, and less scrap is produced.

AM also can be used for functional prototyping and replacement parts. This gives companies a speed advantage, improving flexibility and agility by reducing product development time and manufacturing lead time. Printing replacement parts on demand can reduce inventory carrying costs in companies and improve logistics and support in military operations, especially in remote locations.

Reduced tooling needs make AM useful for customized parts and components. This enables new “manufacturing as a service” business models that entrepreneurs and startups can exploit for low-volume production runs of customized product offerings. Larger companies can use AM to print custom tooling, fixtures, patterns and molds for low-volume production runs.

Part consolidation reduces assembly time as well as labor costs. It also can reduce procurement costs and supply-chain complexity. Part consolidation can improve the structural integrity of parts and reduce possible leakage points in manifolds and other high-pressure applications.

AM can produce intricate internal channels to lightweight components or improve heat-transfer efficiency in piston crowns or turbine blades. Conformal cooling channels inside an injection-molding tool can speed production by improving cooling efficiency. The surface roughness inherent in AM builds actually helps improve the heat-transfer efficiency of heat exchangers, opening avenues for new geometries that better conform to their use.

By bringing AM in house, companies often can gain additional leverage over their supply chains, reducing procurement costs. Testing and component validation can be expedited. Inventory costs can be reduced by moving to digital inventories that leverage AM’s on-demand manufacturing capabilities, like printing when you need it. This increases flexibility by making the company more nimble in response to fluctuations in the market. Companies then can deliver products more quickly or deliver a higher-quality product closer to when it is needed.

The benefits of AM are many, and the challenge arises because the value proposition can vary widely by application, company and industry. Understanding the opportunities as well as the restrictions is important to getting the most out of AM and ensuring that your part will fly not just because it is cool, but also because it brought value to the end product just like everything else.

Related Content

Pivoting to Additive Manufacturing for Individuals and Organizations: AM Radio #29B

The pivot to additive manufacturing requires interested individuals as well as support from the top. In a recent episode of AM Radio, we discuss workforce development from the inside and strategies for implementing AM across an organization.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreTop 5 Additive Manufacturing Trends You Can't Miss

Additive manufacturing has made significant strides since the last IMTS. Here are some of the trends to watch for from this year’s conference.

Read More3D Printed Spares, Electrification and Cool Parts: Top 10 Stories of 2022: AM Radio #31

Our top articles and videos from 2022 reflect increasing use of additive manufacturing for replacement parts; growing applications for electric motors; and a maturing user base. Read through the top 10 list or listen to the AM Radio podcast episode all about these stories.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More