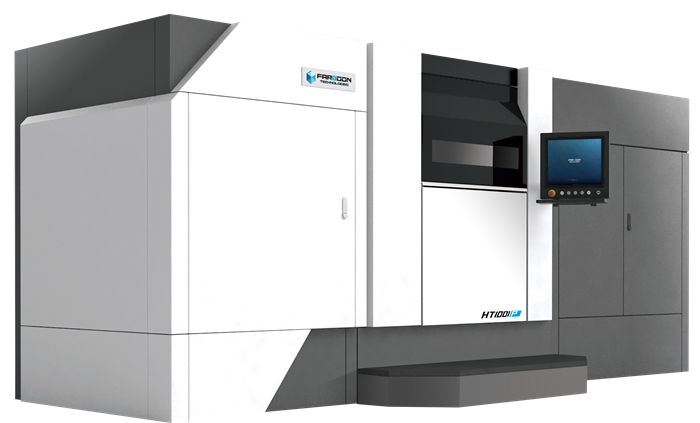

Farsoon Technologies’ Large-Volume Polymer 3D Printer Debuts in U.S.

The HT1001P, Farsoon's new large-volume polymer 3D printer, is set to be beta tested by two U.S. companies later this year. The system will eventually offer three tiers of automated production.

“A company starting in 3D printing is at the beginning of a long journey, and the goal of industrialization is still very far away.”

This is Dr. Xu Xiaoshu, an additive manufacturing pioneer who served as technical director at the industry's first laser sintering company in the early 1990s. But industrialization is coming, he adds, and likely sooner than anyone expected. Dr. Xu is founder and CTO of Farsoon Technologies—a company whose name is said to derive from Xu’s sentiment above, as well as a quote attributed to him about “traveling far, soon.” In any case, the company’s new North American sales and technical center is indeed a long journey from Farsoon’s headquarters in Hunan, China. Now with branches in North America and Europe as well as reseller networks covering Russia, Korea, Australia and Singapore, Farsoon Technologies calls itself a “total solution supplier of industrial grade plastic laser sintering and metal laser sintering.” The company aims to serve the market by offering scalable productivity toward additive manufacturing industrialization at reduced operational costs.

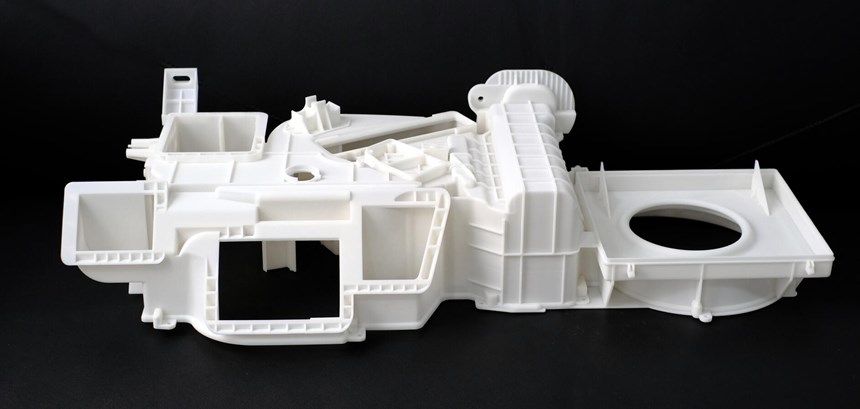

Farsoon’s newest offering is the HT1001P, a large-volume polymer production machine branded as a “continuous additive manufacturing solution (CAMS)” system. Like all Farsoon machines, the HT1001P is an open system that allows users to freely select materials and adjust parameters and configurations to suit their requirements. With an expansive build size of 1,000 × 500 × 450 mm, the HT1001P’s multi-laser scanning capabilities allow for production of single or multiple assembly parts in high-performance materials due to the build chamber’s ability to control temperatures up to 220°C. The automotive HVAC ventilation unit shown in Figure 2 measures 950 × 440 × 218 mm and was 3D printed as a single piece in 10 hours with Farsoon’s FS3300PA nylon 1212 powder. While the machine won’t be available for purchase until early 2019, two beta customers in the U.S. have been selected to install the machine later this year.

Chuck Kennedy, Farsoon’s vice president of operations in the U.S., says that improvements are still being made to the HT1001P, including three options that each enhance automation and speed. The first option is a preheat build station that enables faster turnover between powder cartridges. Option two, which Farsoon is still testing, will offer a modular cooling station that actively cools down the powder cake—a process that, when allowed to happen passively, can take as long as 20 hours to cool down for a part that takes 20 hours to build. Kennedy notes that Farsoon’s current 403P series system has the capability to cool down the powder cake outside the system, but says the HT1001P—which the company says will be on display at Formnext this November—will be much less dependent on operator intervention. Finally, Kennedy says that option three will offer improved automation on de-powdering, self-mixing and material recycling. Kennedy estimates that option three—which he says represents “a completely closed-loop powder-handling system”—will be available in mid-2019.

Related Content

-

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

-

Aluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

-

Multimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.