FAA Clears First Additive Manufactured Part for Flight in a GE Commercial Jet Engine

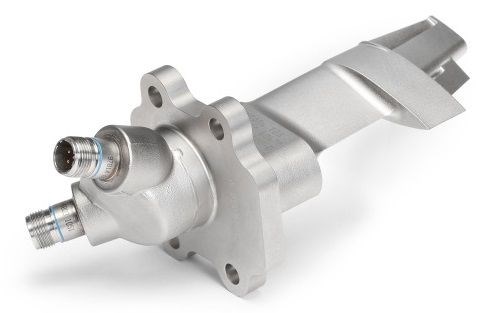

A cobalt-chrome temperature sensor housing is being retrofit to GE90 engines used by Boeing.

Share

GE Aviation has announced that the cobalt-chrome housing for a compressor inlet temperature sensor has become the first additive-manufactured part to be certified by the U.S. Federal Aviation Administration to fly inside GE commercial jet engines. The company has begun working with Boeing to retrofit more than 400 GE90-94B jet engines with this new part.

This housing won’t be unique for long, the company says. Flight tests are underway for the LEAP engine, developed through a joint venture between GE Aviation and France’s Safran, which uses 19 additively manufactured fuel nozzles. This engine is aimed at new, narrow-body planes such as the Boeing 737MAX and the Airbus A320neo, and GE says more than 8,500 orders for the engine have already been received.

Read more in this statement from GE.

Related Content

-

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

-

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

-

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

.jpg;width=70;height=70;mode=crop)