Experiment Tests the Reusability of Titanium Powder

Renishaw ran the same batch of powder through build after build, evaluating it each time. The results support the viability of AM for ongoing production.

Share

Read Next

One of the promises of additive manufacturing in metal is reduced material use. An intricate form produced additively can be grown to its final shape or very near to it, whereas the same form produced through a more conventional process might require much of the workpiece material to be machined away as chips.

And yet, that promise rests on an assumption. It assumes that the powder metal in a powder-bed additive process can be recycled. If it cannot—that is, if unused powder from one build is precluded from making a part in the next build—then this compromised material is just as wasted as any chip. Therefore, the material efficiency of additive manufacturing is determined by the reusability of the metal. Just how far can an additive metal machine go with a single batch of powder? This is an important question.

Marc Saunders and Lucy Grainger of Renishaw Inc. recently reported on an experiment addressing this question. Mr. Saunders is the director of Renishaw’s Global Solutions Centers, and Ms. Grainger is a product marketing engineer for the company. Work carried out with titanium 6Al4V alloy in a Renishaw AM250 machine using a 200-W laser tested whether repeated reuse of unused powder in build after build affected the characteristics of either the powder itself or the parts it was used to make. The short version of the findings—which are very encouraging to the prospects of AM for production—is that neither the process nor the parts were much affected by re-using material.

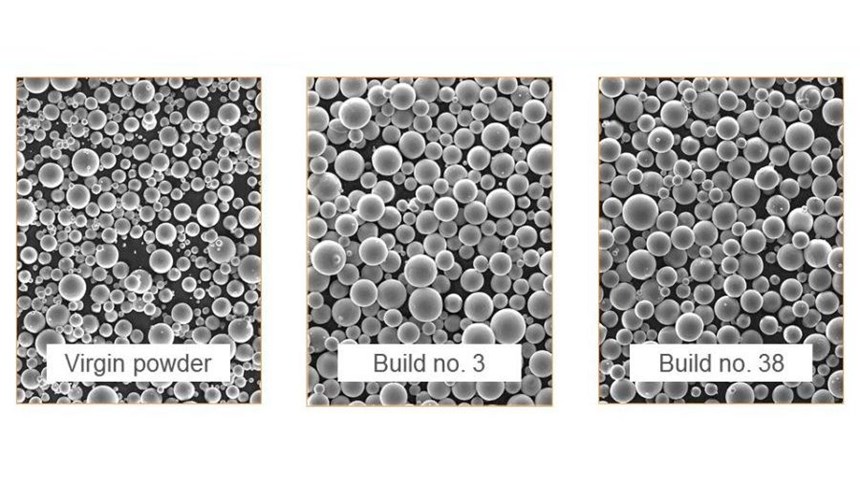

The company’s experiment tested a scenario far more extreme than any production process is likely to be. An initial batch of powder was used and reused without the powder ever being replenished. After 38 build cycles were run, there wasn’t enough powder left to make any further parts. In production, powder wouldn’t be used this way—virgin powder would continually be blended into the mix, diluting any problems that the previously used powder might present. The Renishaw experiment deliberately aimed to unmask those problems, if they exist, by removing the dilution. In other words, this wasn’t a simulation of production; it was a simulation of the far more demanding case of a manufacturer somehow marooned with an additive machine and just a single bin of titanium powder.

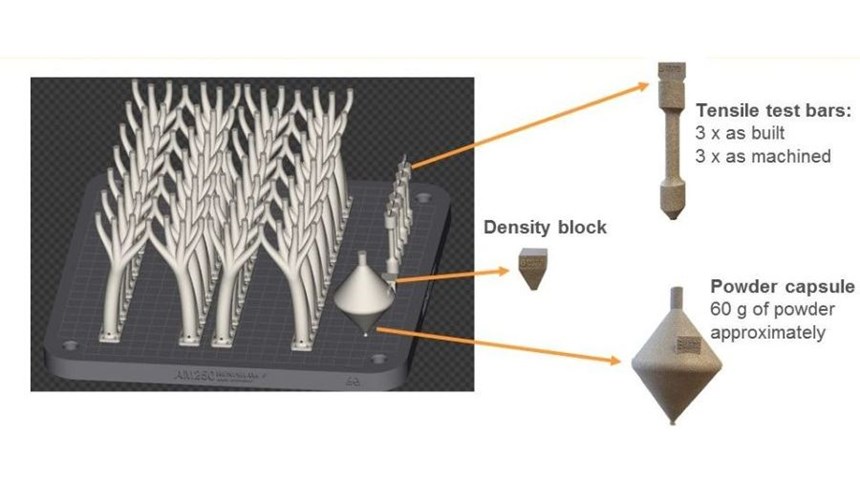

Technically, some powder was indeed lost. Powder re-use entails sieving to remove grains that have become fused because of their proximity to the additive weld. However, this sieving removed less than 1 percent of the material, Ms. Grainger reports. All of the rest of the material except for the remnant at the end was used to make complex forms representing production parts, plus test pieces such as tensile bars.

Powder consistency, powder flowability, material chemistry and the mechanical strength of the metal were all evaluated from build to build. While none of these parameters remained constant, none of them changed enough throughout the testing for the change to be significant. For example, the slight measured increase in oxygen and nitrogen contamination across the 38 builds remained well within the margin allowed by the relevant standard, ASTM F3001-13. Powder flowability actually improved.

The results of this experiment can’t be extrapolated, Mr. Saunders says. Different materials might respond to re-use in different ways. Other machines will also behave differently. He points out that the Renishaw machine seals its build chamber, evacuating moisture and contaminants before replacing the atmosphere with argon. But even so, this set of findings provides a promising and even exciting early step toward qualifying powder-bed systems and materials for production. Read Mr. Saunders’ more detailed report here.

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More