When Michael Rappach first began working for NextStep Arthropedix, a medical implant company owned by Randy Theken, he was faced with a difficult task: finding a contract manufacturer that could produce the hip and knee products designed by Theken's in-house engineering team. The catch? These medical devices, made from titanium with a trabecular surface structure to mimic cancellous bone, were intended to be manufactured additively. It turned out to be a tall order to find an outside contract manufacturer that could serve as an end-to-end supplier, with the understanding and equipment for metal additive manufacturing (AM) as well as the capability to meet stringent requirements for final machining.

This dilemma ultimately resulted in the creation of Slice Mfg. Studios, part of the Theken organization that serves as a contract manufacturer not only for its sister companies but also for outside customers ranging from medical device to aerospace companies. Today Rappach is its vice president of manufacturing. Slice is located in a newly constructed 40,000-square-foot facility in Akron, Ohio, next door to the historic Akron Airport Terminal building built in 1929, which became Theken’s world headquarters in 2005 (Figure 2). The area is surrounded by Northeast Ohio history; other landmarks within sight of the facility include the Goodyear Air Dock, formerly the home of the Goodyear blimp, and the remains of the Rubber Bowl stadium where University of Akron football teams once played.

But amidst these reminders of days gone by, Slice has a new and hopeful gleam about it. Everything about this facility has been designed with the end goal of manufacturing complex parts that other contract manufacturers may choose not to attempt, and doing it in the best, safest and most controlled manner possible.

This meticulous mindset can be seen clearly in the company’s approach to producing medical devices, for instance an acetabular hip cup designed by NextStep Arthropedix that is built additively and then machined. Once the titanium powder for these implants enters the building, it leaves in only one of two ways: as waste to be returned to the supplier, or as a completed medical implant that has been sterile cleaned, sterile packed, labeled, shrink wrapped and made ready for direct delivery to the customer.

Compartmentalized and Controlled

Slice Mfg. Studios falls under the umbrella of Theken Companies LLC, a group that also includes NextStep Arthropedix, NextStep Extremities, NextStep Spine and other Theken affiliates. Slice first began additive manufacturing in a rented laboratory in 2015, and in 2017, moved into the purpose-built facility adjacent to the airport terminal headquarters. This building supports both additive and subtractive operations, with multiple Willemin-Macodel robotic five-axis machining/turning centers, Tornos Swiss-type screw turning centers and Sodick wire EDMs, in addition to Arcam electron beam melting (EBM) 3D printing systems for titanium and a 3D Systems laser-based metal 3D printer used for stainless steel. Some of the machining capacity is devoted to machined products such as bone screws produced on the Swiss-type lathes; other systems, such as two Willemin multitasking centers equipped with automation, are used for postprocessing 3D-printed implants.

The entire facility is compartmentalized based on steps in the manufacturing process. Many operations take place in designated rooms behind closed, labeled doors (Figure 3) to keep process steps separate. The building has a clinical feel to it—more hospital or research lab than machine shop—but there's no denying the very real, highly controlled manufacturing that takes place inside.

The process for manufacturing the acetabular hip cups begins like that for any other medical or aerospace component that Slice produces additively: by sample testing every batch of powdered metal that comes through the door in a Leco elemental analysis machine. The titanium powder arrives in sealed bags from the manufacturer (in this case, AP&C, an Arcam company), which are opened to remove a sample, and then resealed to minimize exposure.

Once approved, the virgin powder is used in the company's Arcam Q10 EBM machines. To prevent sparks and ensure build quality, the EBM machines feature vacuum build chambers filled with helium shielding gas. But ensuring the safety of the process goes beyond the build chamber. At Slice, the EBM machines are housed inside a Class H2 explosion-proof room. A copper rod along the back wall is used by operators to ground themselves while working on the machines. Special filters in the HVAC system trap powder particles, and the room is also equipped with a halon gas system designed to suppress metal fires.

Electron Beam Melting for Medical

EBM systems build parts in a powder bed, using an electron beam rather than a laser as the energy source. But beyond this obvious fact, there are some key advantages to using EBM technology over laser-based systems for medical device applications. For one, the entire powder bed is heated during printing. This slows down the process somewhat, because the machines require a preheating period before printing can begin. But it also offers a major benefit: Parts are essentially heat-treated as they are being manufactured, avoiding the need for a separate heat-treating step.

Another significant difference between EBM and laser-based systems is that the EBM process does not require that the build actually attach to the build plate. Instead, parts can "hover" above the plate and between each other, supported by unmelted powder. This means there is no need to EDM parts off the plate once complete. It also means that parts can be stacked, making fuller use of the space inside the build chamber. Support structures are still necessary in many cases, but they serve more as heat sinks than anything else, Rappach explains.

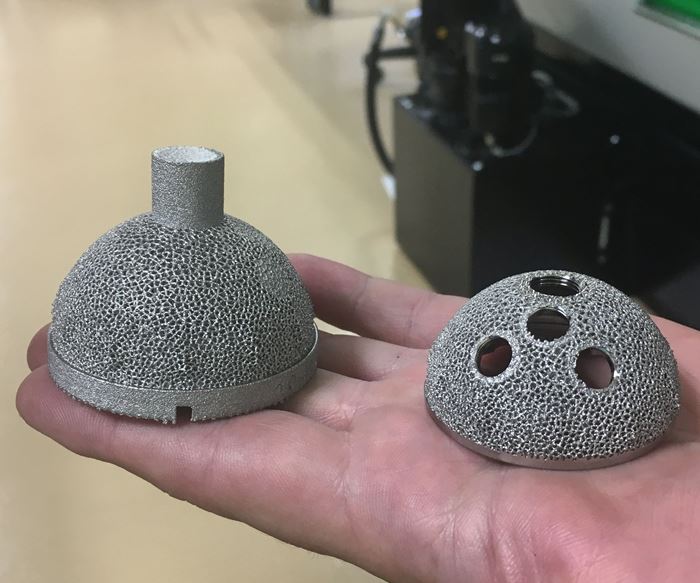

Each of the Arcam EBM machines can produce approximately 70 acetabular hip cups every five days. These implants feature a built-in trabecular texture on the outer surface to encourage bone growth, a feature made possible only through additive manufacturing. Competitive medical devices apply a bone-like texture to machined implants via plasma spray or a glued-on coating; however, this roughness is only surface level, and there is a danger that an external coating could delaminate inside the patient. The 3D printer also adds each hip cup’s serial and part number as well as its layer and row within the build chamber to its outer diameter (see Figure 6).

Once a batch has been printed, the parts and the unmelted material surrounding them are removed from the machines and transferred to the powder recovery room, adjacent to the room housing the EBM printers. Here, parts are cleaned of powder in a special blast cabinet and the unmelted powder is reclaimed and stored. This used powder is quarantined in a different part of the facility for sale back to AP&C, which recycles the used material. Because of the nature of EBM, elements are burned off during the process and it's difficult to know what's been lost; as a result, Slice relies only on virgin powder in its machines.

Postprocessing with Automation

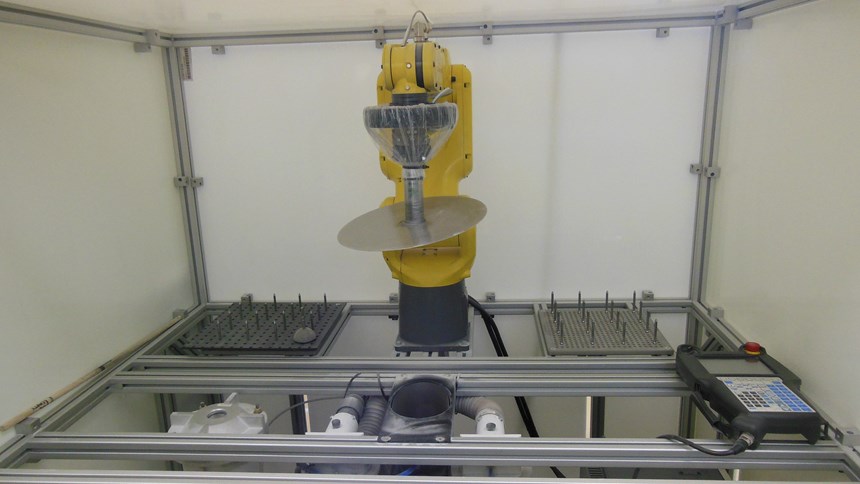

After cleaning with proprietary equipment, the hip cups are finished blasted. This process is fully automated at Slice to eliminate operator error and enable unattended operation. Blasting is performed by a FANUC LR Mate 200iD robotic arm inside a blast cabinet, while custom fixtures hold the parts in place (see Figure 4).

Then the cups move to the main production space for processing on one of Slice's Willemin-Macodel multitasking machining centers with turning capabilities. These machines mill away the central support, smooth the interior of the cup, and drill and tap the holes where bone screws will fit.

Automation is incorporated into the machining steps as well. One of the 508 MT machining centers is equipped with a robot and carousel system with rotating trays that can hold as many as 288 hip cups using custom plastic 3D-printed fixtures (Figure 5). Each component is lifted by the robot and measured with a laser system to determine its diameter. This information is relayed to the CNC to call the correct program for machining, enabling different implant sizes to be loaded on the carousel at the same time. This machining center can process around 100 hip cups per day, more than the Arcam printers can currently produce.

Finishing Touches

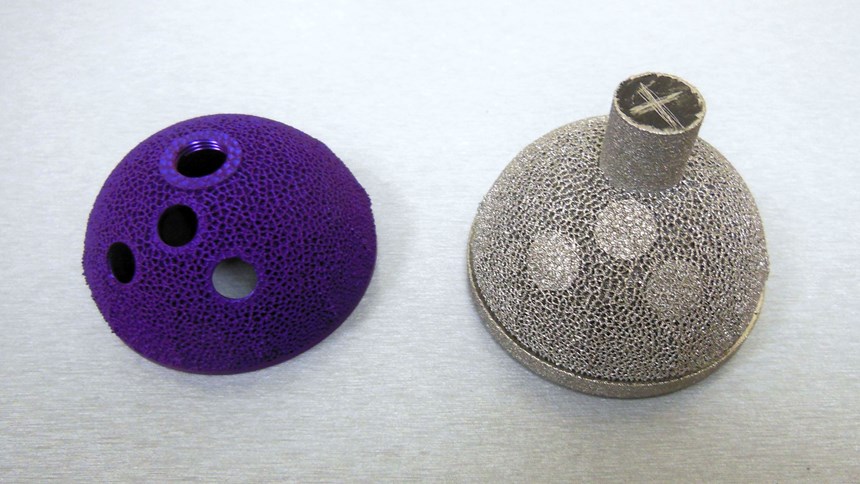

After machining, the hip cups get an unusual touch: They are anodized (one of the few procedures done by an outside firm), resulting in a final color that correlates with plate and bone screw sizing (see Figure 7). Why take this extra step? In addition to helping surgeons easily match implants in the operating room, Slice anodizes the cups in part "because we can," Rappach says. An implant that has been coated to provide a rough surface finish can't be anodized, but the fact that Slice's implants are made completely of titanium with the texture built in makes this possible.

The last stop for the parts before inspection is laser marking to add the hip cup's size and serial number (Figure 8). A Foba M-series laser marking machine makes this process fast and eliminates operator error. The system is able to quickly find the parts on the table, orient the laser to mark them appropriately, and then check its own work once complete.

Slice's inspection equipment includes a Hexagon vision CMM and Olympus elemental tester for nondestructive testing of material makeup; every 3D-printed part is evaluated this way to check its heavy element content. The inspection room also includes a tensile testing machine for testing coupons and a Leco testing machine, a destructive system that heats either metal part or powder to the melting point and analyzes gases that burn off to check their chemical makeup plus oxygen content.

After final inspection, parts pass through an airlock door just large enough for a wheeled cart (Figure 9) into a cleanroom environment for sterilization and packaging. The air quality in the Class 10,000 sterilization cleanroom is continuously computer monitored, and humans must go through a separate gowning area and air shower before entering. Once clean, parts pass through another airlock door into a Class 1,000 cleanroom for sterile packaging, completing the nearly beginning-to-end manufacturing process.

Still to Come

Slice has designed this entire process to ensure quality and traceability. Soon, this level of control could extend even further. When I commented on the available space in the 3D printing room at Slice, Rappach told me it will someday be filled by additional Arcam systems, as well as equipment for analyzing and mixing metal powders. Slice's eventual goal is to be able to control even the powder that goes into its machines, by buying the elements and creating its own custom blends for specific oxygen content, fatigue or other properties. These materials made in-house will need to be certified, which will mean installing additional analyzers for chemical makeup and particle size distribution.

Mobile automation is another addition that could be coming soon. Slice has plans to acquire an Otto Motors automated guided vehicle (AGV) to shuttle parts from machining into the inspection area; in fact, a rollup door for this purpose was under construction at the time of my visit.

"The idea is to ensure complete traceability," Rappach says. Not only would an automated system allow for more unattended operation, it would also avoid delays, like an employee being called away while carrying parts from one stage to the next. When the system is in place, parts will have RF tags so that the AGV recognizes the work it is picking up and the ERP system can be automatically updated.

In just a few short years, Slice has established itself as the type of company that didn't exist when Rappach first went looking: an additive manufacturer with the ability to print, postprocess, clean and ship medical implants, in a manner compliant with ISO and FDA standards. Until recently this capacity has been used exclusively to make NextStep implants, but as of October 2017, Slice's doors are also open to external customers.

Related Content

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreRead Next

Building an Additive Manufacturing Business for Production

What does it look like to build a business based on AM production from the ground up? An Ohio medical device contractor is finding out.

Read More3D Printed Hips Versus the World's Deadliest Mountain

3D printed trabecular titanium hip implants—printed by Lima Corporate on Arcam EBM machines—helped legendary Italian mountaineer Romano Benet to continue scaling the world's most dangerous peaks.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)