Educators and Industry Discuss Need for Engineering Education to Adapt to AM

The National Forum on Additive Manufacturing Education and Training recently held at Penn State University yielded these interesting points.

Share

How should engineering and manufacturing education adapt to the advance of AM? Last week at Penn State University, a two-day conference explored this question. The National Forum on Additive Manufacturing Education and Training was organized by Penn State’s Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) in cooperation with America Makes.

More than 30 speakers shared their insights in various panel discussions throughout the event, which drew attendees from both education and industry.

Here is some of what I took away:

Connecting Conceptual to Commercial

Jack Beuth, mechanical engineering professor at Carnegie Mellon University, described how 3D printing enables him to emphasize the relationship between engineering design and commercialization. Students experience the product development process in a project assignment that requires them to design a 3D-printable product and then attempt to sell it through the 3D printing marketplace, Shapeways.

Starting in the fall of 2017, Beuth says Carnegie Mellon will offer a master’s degree in additive manufacturing as well as an undergraduate minor in AM.

Addition by Subtraction

Krishnan Suresh, professor of mechanical engineering at the University of Wisconsin—Madison, said part of the challenge additive manufacturing presents to universities is finding the capacity within already full programs to accommodate the instruction it requires. For the sake of adding AM, engineering departments need to ask: What are we teaching now that we don’t need to teach anymore? (A possible example: CAD instruction. Given a digital-native generation plus more intuitive software, students today quickly become capable in CAD.)

Enthusiasm Now Is on Tinkering

It used to be that engineering students wanted to design, but were reluctant to engage with manufacturing, observed University of Texas—Austin associate professor of mechanical engineering Carolyn Seepersad. But in the age of 3D printing, she says, the enthusiasm has flipped. Students now want to tinker, often jumping past the design phase. She stresses the importance of appreciating when to spend time in modeling and analysis before proceeding to fabrication.

Challenges for Distance Learning

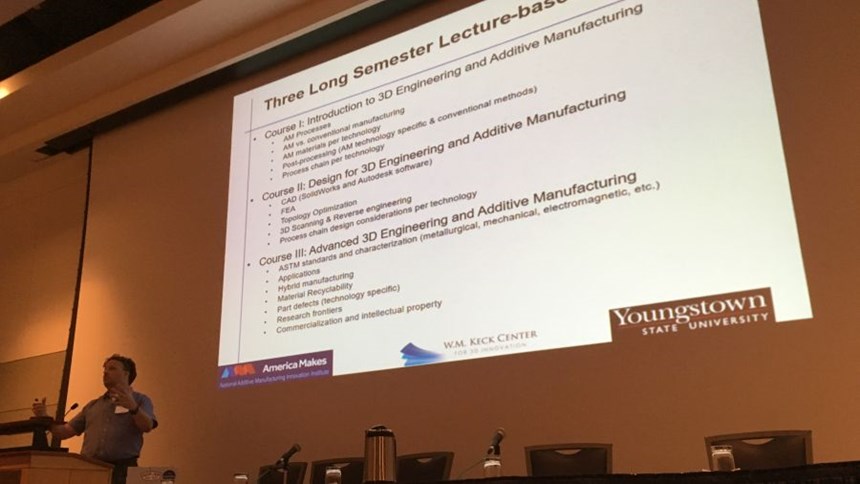

What is the right way to provide working professionals with compressed courses in this technology? Distance learning does not work well with 3D printing, said Eric MacDonald, professor of electrical engineering at Youngstown State University. Understanding the nuances and different approaches to 3D printing requires engaging with the technology. He has participated in the development of two-week intensive courses relying partially on distance learning, but ultimately these courses have to include the requirement that students come to the facility to see the equipment.

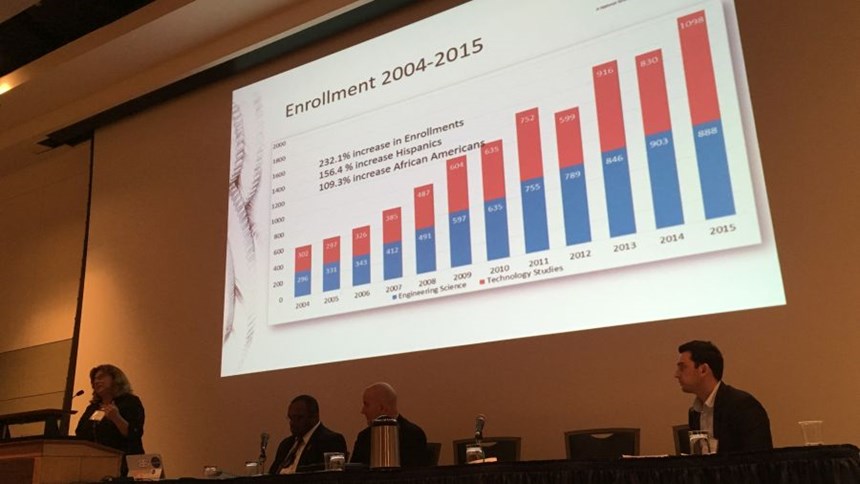

Increasing Enrollment for Community Colleges

Community colleges were also part of the program, as the shift to curricula incorporating AM will need to occur in these institutions as well. Karen Wosczyna-Birch, executive director of the Regional Center for Next Generation Manufacturing based in Farmington, Connecticut, showed an encouraging bar graph related to these institutions. Manufacturing-related student enrollment in her center’s programs has increased by more than 200 percent in the past 12 years, including gains of well over 100 percent in both African American and Hispanic students. She notes, however, that gains in female enrollment are still lagging.

Tooling an Opportunity for Internal Education

I led a panel discussion consisting of manufacturing leaders involved in AM. Panel members represented companies including Boeing, GE, Imperial Machine & Tool, Lockheed Martin, Pratt & Whitney and Siemens Energy.

Bill Flite spoke for Lockheed Martin; he is senior manager of advanced materials and manufacturing for the company. He spoke of the need for training and education within companies that are already adopting AM—as well as the need for winning buy-in. Aircraft-industry manufacturers such as his employer are risk-averse by culture, and necessarily so. They work in a regulated industry, producing a product on which lives depend. The introduction of a novel manufacturing process is met with resistance. That is partly why the value of additive manufacturing for making industrial tooling should not be overlooked, he says. 3D-printed custom tooling not only brings greater efficiency and effectiveness to today’s established processes, he says, but it also creates a safe test case in which manufacturing decision-makers can see AM in action and see how well it succeeds.

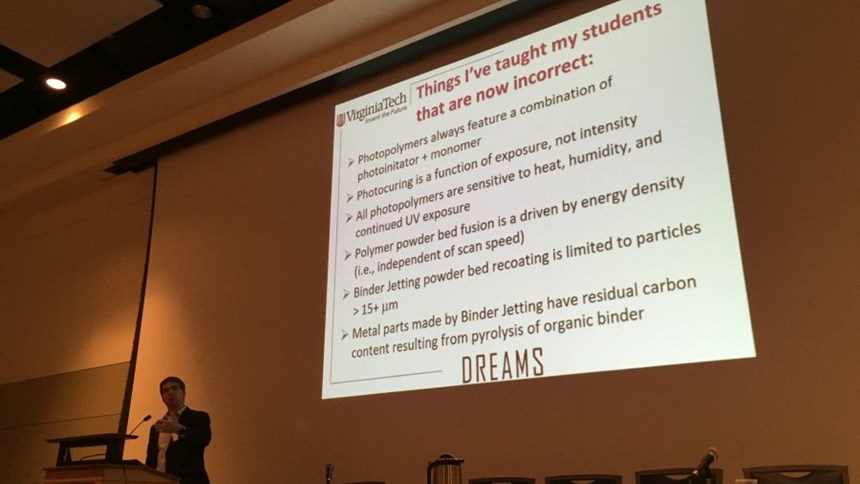

Significance of Removed Constraints

Comments from Chris Williams, director of the Design, Research, and Education for Additive Manufacturing Systems (DREAMS) Laboratory at Virginia Tech suggested that the incorporation of additive manufacturing into college curricula is not necessarily a one-time response to the arrival of a new technology, but perhaps the beginning of a more fundamental change. Arguably no other manufacturing technology removes so many constraints and offers so much potential freedom to engineers. Industry will continue to discover how to apply this freedom. Part of the need he sees is preparing engineers to embark upon and participate in this discovery. “The future of additive manufacturing education is learning how to learn,” he says.

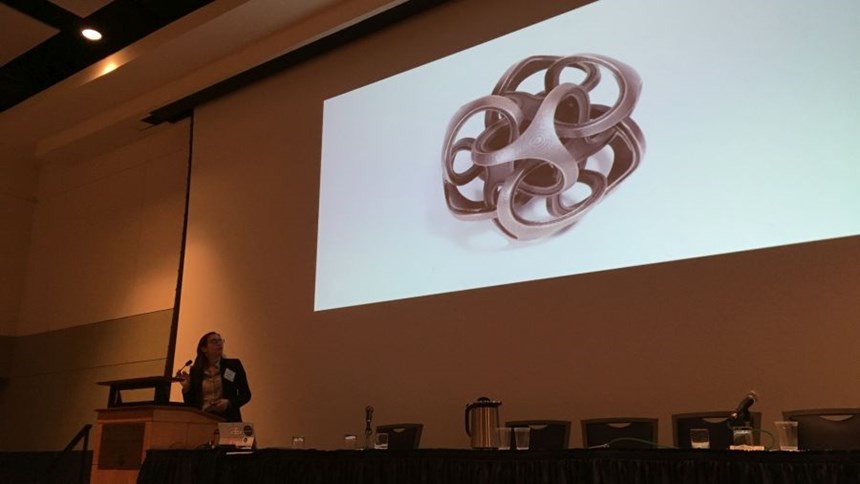

Artists Also Make Demands on AM

Artists have a role to play, says Elizabeth Henry, consumer product manager for ExOne. Along with industry, artists are also exploring metal 3D printing, seeing it as a way to realize works of sculpture that were never previously practical. Far from representing a soft or non-demanding application of 3D printing, artists sometimes make very specific demands that she and others at ExOne have been challenged to accommodate. Artists, too, are pushing the envelope, she says, and industry might make use of innovations that artists pioneer in this space.

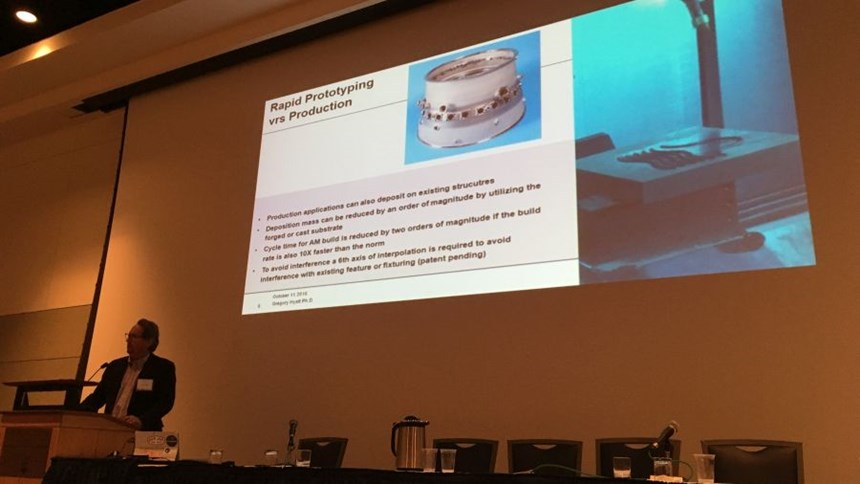

Give Us Students Longer

The learning takes time, said Greg Hyatt, senior VP and chief technology officer with DMG MORI. For part of his presentation, he was a representative of industry speaking to the professors and instructors in the audience. His challenge to them: Let us have students longer. DMG MORI gives interns the opportunity to learn and experiment with the company’s hybrid manufacturing technology combining additive manufacturing with CNC machining, but the time required to do meaningful work and have a meaningful learning experience with this technology is longer than the typical summer internship, he says. He wishes for an on-site internship at the company that could last 4 to 6 months instead. Can universities find a way to allow for this?

He also believes there are elements of an MBA program that would be appropriate for an engineering program tailored to include additive manufacturing. Understanding the economic justification is a big part of recognizing where AM makes the most sense.

Related Content

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreFormnext Chicago Secures Premier Exhibitors for 2025 Event

Companies include some of the premier providers of additive manufacturing technologies as well as startup companies launching new materials solutions, capturing the entire spectrum of AM-related technologies.

Read MoreEOS Helps Strengthen Indiana Tech's STEM Program

Indiana Tech acquires second EOS additive manufacturing system as part of a $21.5 million expansion of its Zollner Engineering Center and STEM educational programming.

Read MoreAM Workshops: The 3D Printing Conferences at NPE and IMTS 2024

We are presenting half-day conferences on additive manufacturing at both of the two largest manufacturing events in North America this year. Join us!

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More