Does Additive Manufacturing Make Sense in a “Subtractive” Machine Shop?

Definitely yes, says this shop—a metal 3D printed part is almost always a machined part as well, and an established machine shop is perhaps the best business to realize AM’s promise for production.

Chris Joest, president and third-generation owner of Imperial Machine & Tool, a CNC machining business in Columbia, New Jersey, sees broad potential application for additive manufacturing. “Go to any industrial concern in this state, and probably you will find at least 5 percent of their manufactured parts could be produced more effectively through additive manufacturing,” he says. However, his shop is not interested in that 5 percent. At least not yet.

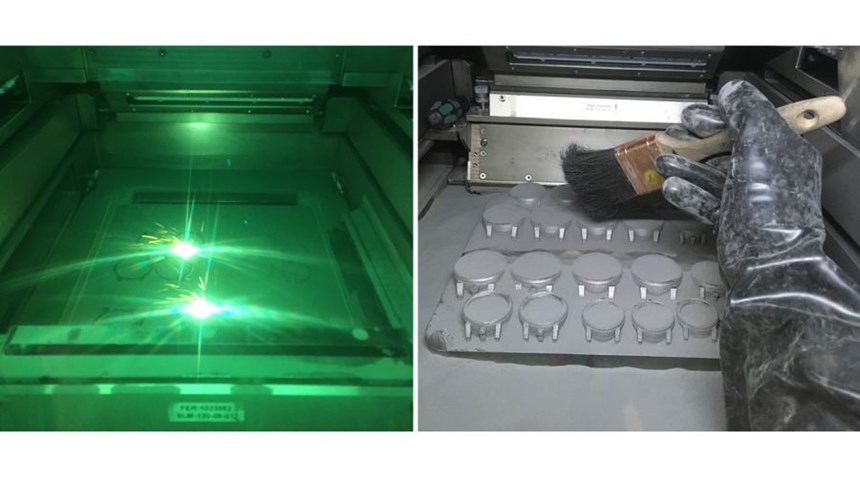

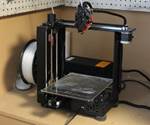

Four years ago, this machine shop of around 40 employees expanded its capabilities to include metal AM, specifically selective laser melting (SLM). Today, it has two powder-bed metal additive machines from SLM Solutions. This resource and this capability are still so unusual in Imperial’s area (and among the suppliers seeking business from Imperial’s customers) that the shop has enjoyed a head start in finding and taking on those applications that can benefit considerably from re-engineering a part to take advantage of the design freedom that AM allows.

“We look for the applications that let us say to customers, ‘We can rock your world!’” Mr. Joest says. As a result, rather than courting the customers that have 5 percent of their parts as candidates for additive, Imperial has been able to succeed by serving customers for which more like 80 percent of their parts might benefit from being remade this way.

I’ve written about Imperial once before, soon after it installed its first SLM machine. That first article’s title was “Learning Curve,” a phrase describing the state of the shop’s embrace of additive then. In the time since, the shop purchased its second additive machine and it has largely ascended at least the steepest part of that curve. Additive work now represents 5 percent of the company’s sales, meaning the activity commands a large-enough share of revenue to be noticed and accepted, even though machining is still far and away the core of its business. Thus, Imperial today illustrates what it looks like for additive manufacturing to be accepted. The shop therefore offers a preview of something other manufacturers likely will also come to see in their own shops—namely, additive manufacturing and CNC machining coming together as two routine parts of production. At Imperial, the biggest part of that coming together consists of the additive staff and machining staff working together to arrive at a processing strategy for every 3D-printed job that makes the best use of both these capabilities.

Additive in a Subtractive Shop

Imperial today is actually a fourth-generation family business, because Chris Joest’s son Christian is also part of the company leadership. In their embrace of additive, the two are following in a tradition. In the 1950s, Chris’s grandfather and Imperial’s founder attained a competitive advantage for the company by investing in precision jig boring. Chris’s father was then an early adopter of numerical control. Developing additive capability is a logical step along that trajectory, and Chris Joest says his grandfather would have been thrilled to see the kinds of components that AM is able to create.

But does it make sense for a machine shop, a “subtractive” manufacturer, to have additive capability? Mr. Joest says it makes far more sense than the alternative of different companies specializing in additive or subtractive capability separately. Machining and additive go together, he says, because every critical part manufactured additively is likely also a precision part, with dimensional tolerances that only machining can achieve. In addition, a machine shop like Imperial that has been serving certain customers and certain sectors for many years already has knowledge and credibility within these contexts that translate directly to succeeding with additive. A company that is able to 3D print is not necessarily equipped and ready to apply 3D printing to industrial production.

In fact, Imperial’s experience so far illustrates why additive makes sense not just for a machine shop, but also for a smaller company. Imperial is just large enough to be able to afford to invest in additive, but it is also just small enough to be nimble in seeking and courting those “rock-your-world” customers Mr. Joest cites. Further, Imperial is closely held enough to remain committed and patient while waiting for successes in AM to materialize, which rarely happens quickly. One of the reasons profiting from additive manufacturing today is so uncertain is because parts in production today have been designed for other manufacturing processes. The demand for additive will come, and that demand will grow, only as fast as one engineer after another comes to see the geometric freedom that additive permits, and comes to create new parts that make good use of that freedom.

Pardon My Vagueness

What are those parts like? That is, what are some of the best cases of parts designed for additive, parts that leverage the rock-your-world freedom?

I can’t show you. Really, I can’t even describe them to a satisfactory level of detail, because I promised that I wouldn’t. Parts I have seen recently at Imperial represent advances valuable enough to their designers that details about the parts are confidential. However, even vague descriptions can help convey the nature of the work the shop is now doing and the benefits it is bringing to customers. Examples of critical components Imperial has made through SLM include:

- High-temperature hardware. A piece of hardware used in making another product will enable the manufacturing process for that product to achieve a much higher temperature than what is possible today. Thanks to 3D printing, an intricate array of conformal cooling channels grown into the form of this piece of hardware will enable the temperature jump. Previously, this item’s cooling came from a collection of exterior tubes assembled through welding. Bringing cooling inside the intricate features of the component through the use of snaking interior channels (channels that could never be drilled) will enable greater application of heat in the process, and ultimately an entirely different class of end product. In addition, now that this hardware component is made in one piece without assembly such as tube welding, the lead time for making the part dramatically improves. Refining the part’s design is also easier, since the engineer involved in the project can just tweak the form slightly and see the change appear in the very next version of the part that is 3D printed. When this part goes all the way into production, says Mr. Joest, he expects that serving the need could fill the capacity of four metal additive machines.

- Cooling array. Another component redesigned for additive manufacturing realizes not only improved thermal performance from conformal cooling, but also weight reduction. Within a sophisticated military device, temperature control of a sensitive system formerly was achieved thanks to a support plate with holes drilled through it for cooling fluid. Now, similar to the case above, channels created additively follow intricate, curving paths to deliver cooling to exactly the spots where it is most needed, while much of the plate itself goes away. The 3D- printed array of channels stands alone as a single lightweight, complex part, without any need for the extra mass of what used to be the plate filling out the rest of the component’s volume. Imperial actually won this job after the engineer involved with it learned what additive could do as a result of a colleague sitting at a desk near him working with Imperial on a different component. Mr. Joest says this kind of internal word-of-mouth remains the company’s best means of advancing its AM capability, as one success frequently leads to the opportunity for another success with the same organization.

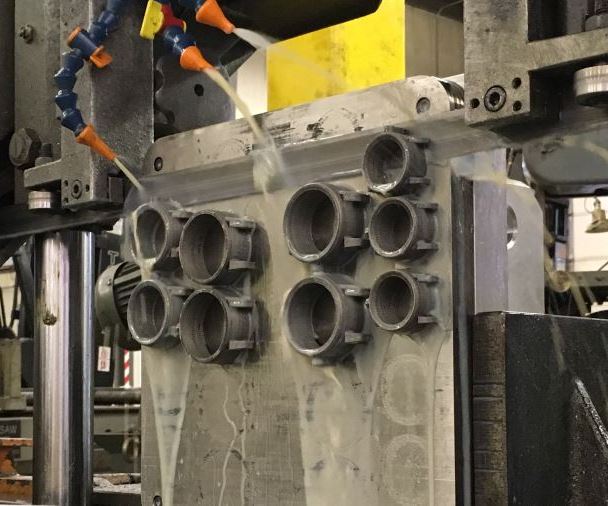

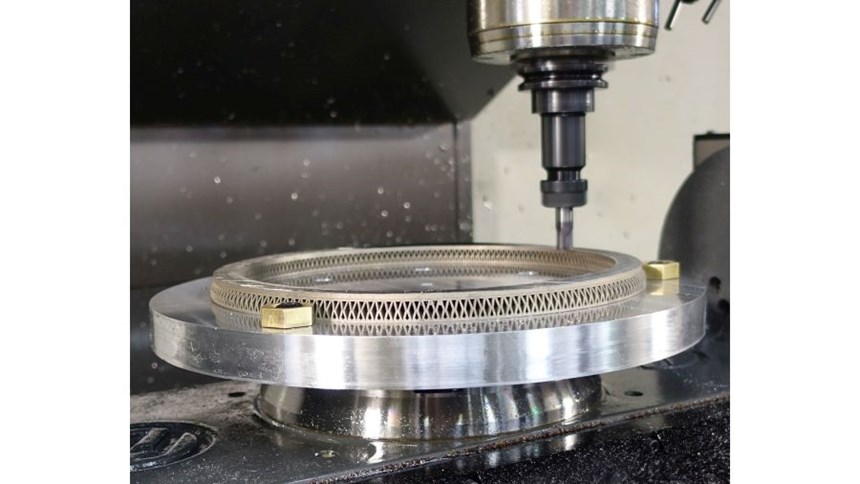

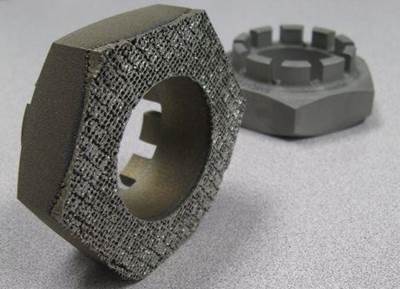

- Converging features. One final component reinvented for additive involves dozens of nozzles each extending from the part at a different angle, all of them aiming toward a common focal point. Mr. Joest and the Imperial staff have been given particularly little insight into the end use of this part; they were simply asked to participate in improving it through additive. A previous version of the part was an assembly in which holes were drilled at the various angles and the nozzles were screwed in. The 3D-printed version eliminates the assembly, but it does not eliminate the multi-angle machining. In fact, the machining actually becomes more challenging in the additive version, because the external features of the 3D-printed nozzle forms all had to be machined at different angles to attain their final tolerances. Part of succeeding with additive in this case was confronting and overcoming this five-axis machining challenge. Experienced machinists were part of the conversation about this project from the beginning, and their input directly affected the redesign. The minimum clearance they could manage for five-axis machining around the nozzles dictated how close the nozzles could be to one another within the 3D-printed form.

Mr. Joest says this kind of joint participation between additive and machining staff was not an unusual feature of this job, but instead is much closer to what is typical for sophisticated parts made through AM. On the nozzle part, the amount of conversation was unusual (working out this design and process took days), but the conversation itself was not. AM has to be coordinated with other operations for most of the parts it is used to make, which means the needs of other operations have to be considered before the design is final and before 3D printing begins. Recognizing this, Imperial has now integrated additive into a shop-wide process in which additive is no longer something special but instead has a seat at the table that is equal to all of the other contributors to a given job’s success.

Fitting In

Now, additive manufacturing is a “work center” at Imperial. This is the company’s term, which might be understood as “department” or “stakeholder.” Vertical milling, horizontal milling, turning, sheet metal, assembly and quality assurance are all work centers here. Before additive ever appeared, team members representing each work center relevant to any particular job would all come together to discuss how that job would be carried out. One work center frequently had to provide for the needs of another. Specifically, the needs of either assembly or QA might affect the way a part is machined. Now, additive engages in the same conversation in much the same way. Often, it needs to defer to some consideration that another work center in the process requires.

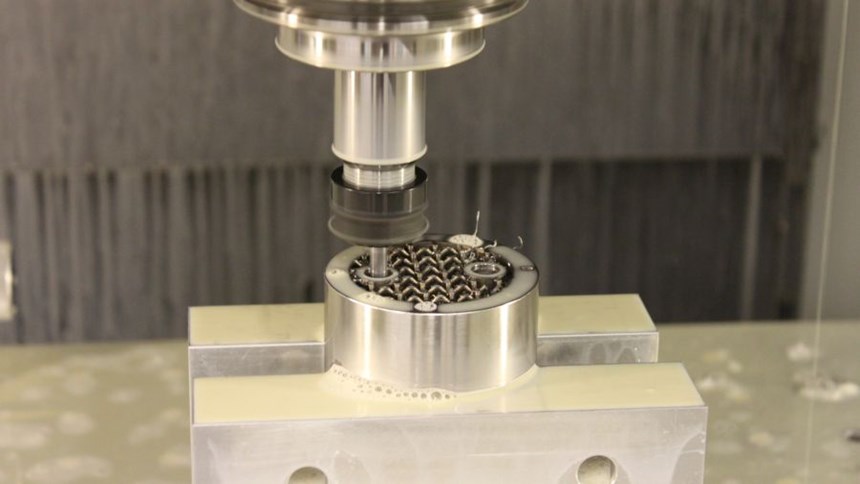

Meanwhile, though, additive also brings freedoms to this conversation that might remove considerations from other steps. In additive manufacturing, for example, holes no longer need to be round. They can be grown to any cross-sectional profile that makes sense for the part. This small change may seem simple, but the expectation that any passage through the part has to be a round, straight hole machined via drilling can be difficult for experienced personnel to abandon. One of the first contributions the staff familiar with additive might therefore make is a re-evaluation of which machined features of the part even need to be machined at all, along with which features truly need to conform to solid or simple geometric forms. In some cases, for example, a solid portion of the part might be reduced to a lightweight lattice or left off the part altogether.

But the concession that additive manufacturing generally has to make is this: It has to leave some material on the part for the sake of overall producibility. An ideal part design perhaps can afford to abandon all of the metal that isn’t purely necessary to the function of the part, but a part that is producible cannot do this. Machining might need to keep some stock in place in order to have a sufficient envelope to cut away to attain a tolerance. Machining might also need stock left over in the form of sacrificial tabs just for the mundane sake of clamping the part on the machining center’s table.

In fact, the most significant mark of additive manufacturing’s advance into mainstream production at Imperial is probably this detail: the extent to which AM parts obey the same day-to-day clamping and workholding considerations as parts made on other processes. For setup efficiency, and for interchangeability among its machines, Imperial has all of its vertical machining centers equipped with an identical pattern of bolt holes on the table. Setups and fixturing for machining jobs are always designed to fit this hole pattern. This is routine practice for the shop, and it has been for a long time. And now, it is a routine aspect of 3D printing as well. When SLM parts are grown with additional tabs for the sake of holding, the pattern of those 3D-printed tabs is chosen to match this same bolt-hole pattern that is used by any other job moving through the machine shop.

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreRead Next

Learning Curve

A manufacturer that has succeeded for three generations expects additive manufacturing to be part of the reason why it will succeed in the fourth. One year into its investment in the technology, here is the company’s experience so far.

Read MoreWhy Your Machine Shop Will Have a 3D Printer

In the future, we’re likely to take it for granted that small machining businesses routinely use 3D printing as a complement to their machine tools. The 3D printer can do work that frees up the more valuable machines.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More