Direct Metal Technologies Tackle the Impossible

Rapid prototyping, rapid tooling and rapid manufacturing are not the phrases used in discussions of direct metal systems. While speed (rapid) is inherent in the process and critical for success, there is much more to the technologies that produce metal parts and tools through direct, additive processes.

Having learned that small decreases in time and cost may not motivate industry to adopt a technology, the vendors of direct metal systems now seek to deliver the impractical, unthinkable and impossible. In the early- to mid-1990's, rapid prototyping systems that produce metal parts (AKA direct metal technologies) targeted time reduction through rapid tooling. But, rapid tooling never really took off since it merely replaced machined tooling with a slightly faster process. Fortunately, direct metal systems are not poised to repeat the failures of the past.

Today, the makers of these technologies are targeting "high value proposition" applications. Not surprisingly, this means that no one is talking about replacing machined tooling to save a few days or a few dollars. Direct metal processes now seek to change and improve manufacturing. These additive technologies target the development of advanced tooling, repair of existing structures and manufacture of production parts.

More than Rapid Tooling

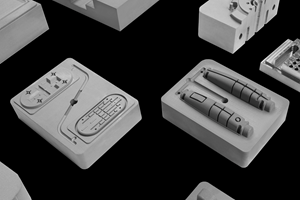

While rapid tooling is no longer the focus of direct metal systems, Solidica (Ann Arbor, MI) and EOS (Tucson, AZ) view it as a viable application. However, the companies do not believe that speed is the key benefit. Instead, they see the advantages of self-contained, push button devices to produce prototype or short-run tools. With direct metal technologies, manufacturers can bring tool making in-house without the effort and expense of acquiring multiple machine tools, creating new processes and training staff.D-M-E (Madison Heights, MI), a leading supplier of tooling components, downplays rapid tooling. Although the company's MoldFusion division originally sought to build tools faster, it now has its sights set on reducing molding cycle time. MoldFusion, which is partnered with Extrude Hone (Irwin, PA), uses direct metal systems to make thermally efficient inserts for high volume production tooling. With conformal cooling, which is impossible with machined tooling, MoldFusions's tooling inserts can improve plastic molding productivity by upwards of 50 percent.

Like D-M-E, Optomec (Albuquerque, NM) and POM (Auburn Hills, MI) have also adopted cycle time reduction as a primary benefit of their powder deposition technologies. These companies capitalize on the systems' abilities to deposit multiple alloys and blend them on the fly.

Alternatively, both technologies can deposit metal alloys on a machined perform. Either way, production tooling can have both the thermal conductivity of copper and the wear characteristics of H13 tool steel. The result is extended tool life and drastically reduced mold-ing cycle times.

Repair and Reconfiguration

Rebuilding, reworking and re-pairing tooling is expensive and time consuming. Since Optomec's and POM's direct metal technologies can deposit metal on an existing tool, both can extend the life of a tool or salvage a mold that cannot be reworked with conventional technologies. Without the limitations of welding, a tool can be put back into service quickly, and production can continue without interruption. Solidica's process can also deposit metal on existing struc-tures. But instead of applying the technology to tool repair, the company believes that the future is in part repair. For example, there are a lot of aging aircraft that need frequent repairs. With direct metal systems, the parts can be repaired in the field, which reduces downtime and cost. The government believes that direct metal technologies can also be used to make advanced structures. Solidica recently received an SBIR grant to develop a new approach for retrofitting existing military vehicles with ballistic protection that can be applied in the field. The process includes embedding both ceramic armor plates and threat detection fiber optics directly within the armor components.Direct Digital Manufacturing

There is a lot of activity in the area of titanium part building for aircraft and medical implants. Accufusion, Arcam, AeroMet, EOS and MCP are all vying for a leadership position in the direct manufacture of titanium components. Direct metal technologies can overcome the challenges of casting titanium billets and welding titanium parts. They also reduce time and expense, when compared to machining, while incorporating previously impossible geometry to improve strength to weight ratios. The aircraft industry is an early adopter of direct metal technology. AeroMet has production orders for titanium parts for both the F-15 and C-17 aircraft. Recently, Arcam announced that Boeing's Phantom Works has purchased a system to produce Ti 64 aircraft components. Arcam envisions aircraft with advanced components that could not be cast or machined. To improve strength to weight ratios, parts will have an inner scaffold that is skinned with a layer of titanium. MCP also focuses on the production of complex metal parts in titanium and other alloys. But the company notes that it has no intent to replace high-speed machining or other material removal processes. Instead, the direct metal technology will be an alternative for complex shapes that are challenging, or impossible, for conventional technology.These are just of few of the applications for direct metal systems, and they are just the tip of the iceberg. Unparalleled in process and capability, there are countless applications for direct metal systems that have yet to be recognized. The common denominator for both current and future applications is that the technology can do much more than shave a few days or few dollars from a project.

Obstacles and Opportunities

The manufacturers of direct metal systems cite risk aversion as the primary obstacle to the adoption of the technology. The challenge is finding those companies that are open to new processes, and within those companies, finding the visionaries that are will to accept risk for the potential of huge gains. Entering a field where the fundamental processes are long established, direct metal systems must prove that they can do the unthinkable and impossible in order to unseat conventional practices and disrupt conventional thinking. Broad use in three to five years may be idealistic, but with industry's support, it will not be much longer than that for direct metal technology to become a common practice for parts and tools. For now it seems to be the visionaries and risk takers that are reaping the rewards. But when the majority begin to use direct metal technologies, it will revolutionize the world of manufacturing.For more information, please contact Todd Grimm, Grimm and Associates, Inc. (Edgewood, KY) at (859) 331-5340.

Related Content

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More