Conformally Cooled Injection Mold Reduces Cooling Time by 55 Percent

With Renishaw’s help, Kärcher ended its production bottleneck using 3D-printed molds with conformal cooling channels.

Alfred Kärcher GmbH & Co. KG sells millions of its K2 high-pressure washers worldwide every year. Producing enough units to meet this global demand, however, is not without its challenges, and the washer’s signature bright yellow casing had become a production bottleneck that restricted the number of units the company could manufacture. To address this problem, the company turned to Renishaw-owned LBC Engineering, which used additive manufacturing (AM) techniques to produce a mold with complex cooling channels. Using this new mold, Kärcher was able to drastically decrease the molding process’s cooling time, meeting the factory’s production goals.

As Kärcher products have grown in popularity worldwide, the German manufacturer has tried to keep pace with global demand. The company produces its signature yellow plastic casing for the K2 series washer on six injection molding machines, each capable of molding 1,496 casings every day, for a total of 8,976 casings daily. The four assembly lines, however, have a production capacity of 12,000 K2 washers every day, exceeding the capabilities of the molding process.

Researching the Problem

To meet the capacity of its production line, the company needed to increase the number of casings it produced. Rather than purchasing more molding machines, Leopold Hoffer, coordinator for injection molding at Kärcher, believed that improving the process could increase the productivity of the existing machines. “Our aim was to reduce cycle time from the original 52 seconds to between 40 and 42 seconds,” Hoffer says. To accomplish this, the company turned to LBC Engineering, part of Renishaw GmbH.

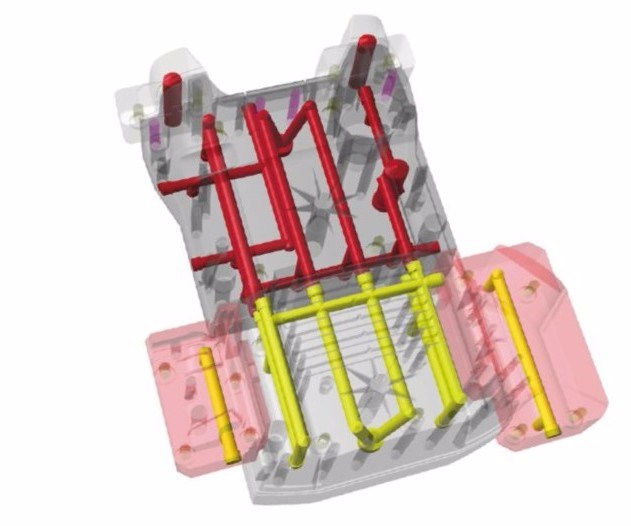

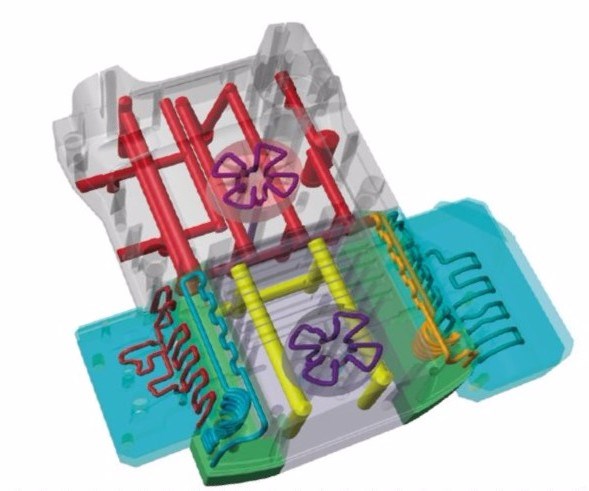

The Renishaw engineering group started by collecting data on the molding process, using thermographic images provided by Kärcher to simulate the existing mold using Cadmould 3D-F software. The simulation revealed that cooling accounted for 22 seconds of the 52-second cycle time, with melting at 220°C and de-molding at 100°C. The simulation identified hot spots responsible for much of the length of the cooling time, and the Renishaw engineers determined that traditional cooling systems, drilled in straight lines, would not be enough to deal with these hot spots. Instead, the company turned to metal additive manufacturing to build conformal cooling channels directly into the mold.

A Conformal Solution

Renishaw proposed a modified mold design featuring two 3D-printed cores to provide conformal cooling at the identified hotspots. Simulations showed that the 3D-printed conformal cooling channels would reduce wall temperature in the molds by 40°C to 70°C, shortening cycle time by 22 to 10 seconds, a 55 percent reduction.

Kärcher confirmed these results and implemented the new molds into its production line in conjunction with some adjustments to peripheral components such as the material feed and handling system. As a result, cycle time has dropped from 52 to 37 seconds, with the lion’s share of that reduction provided by the shortened cooling time. This reduced cycle time has increased the number of K2 casings a single molding system could produce, a jump from 1,496 to 2,101. Between six molding machines, this increase more than met the goal of 12,000 units produced every day.

Though he had been skeptical of the project, Hoffer was pleased. “At the end of the day, the results were better than expected,” he says. “Renishaw sold us a complete improvement package with a holistic consideration and analysis of the mold used to achieve the best results. In our case, this meant a mix of conventional cooling technology, project-specific cores produced using additive manufacturing, and vacuum-brazed cores.”

With the improvements to the cooling system enabling the full utilization of the assembly lines, Hoffer has realized the importance of cooling considerations. “In the future,” he says, “we will give more attention to cooling in the design phase. Cooling calculations will be an essential stage of each mold design at Kärcher.”

Related Content

New Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More