Can Microscale 3D Printing Reduce Surgeries for Glaucoma Sufferers?

Boston Micro Fabrication (BMF) is exploring this promise. Eye stents are made of metal today. Fine-detail additive manufacturing can enable polymer instead, improving patient experience.

Additive manufacturing (AM) sometimes offers a simpler approach to production compared to conventional manufacturing, but just as often, AM is chosen because it permits a design advantage other processes cannot achieve. Eye stents used in glaucoma surgery might be an application that achieves both. Microscale 3D printing promises to simplify how these eye stents are made, while also improving the experience for the patient by reducing the number of glaucoma surgeries from two to only one.

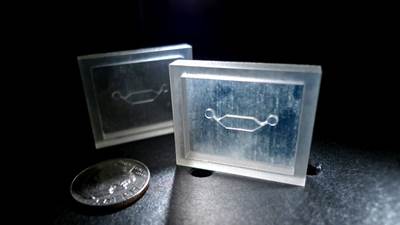

The 3D printed eye stent for glaucoma surgery is about 1 mm long. Photo courtesy BMF.

All this is still speculative. 3D printing technology provider Boston Micro Fabrication (BMF) has been working with a maker of eye stents to explore and validate the possibility. But BMF CEO John Kawola recently described to me the promise of this application.

Glaucoma stents today are tiny precision implants about the size of an eyelash produced through microscale CNC machining of titanium. The purpose of the stent is to provide small channels in the patient’s eye that can drain fluid to reduce pressure. Micromachining these fine parts is a challenging operation relatively few manufacturers are equipped to do, Kawola notes.

BMF sees an opportunity because the company’s focus is 3D printing technology for microscale work. It has developed a microscale 3D printing platform employing digital light processing (DLP), or curing resin to produce solid parts, a technique others have proven for production. BMF adds to this process precision optics and a machine bed with precise X-Y movements, all to enable 3D printing to an X-Y resolution of 2 microns. The result is much easier microscale production. Micromolding and micromachining are both more difficult than their macro-scale equivalents. But 3D printing a tiny part on BMF’s machines can be just as straightforward as 3D printing a larger part.

Parts that require “holes down to 20 or 30 microns in diameter, or walls down to 30 or 40 microns in thickness” represent “a portion of the market we feel has not been served well by 3D printing in the past,” Kawola says. Implants such as eye stents for glaucoma surgery are part of this portion of the market, as are tiny electrical connectors and microfluidic components. Indeed, the 3D printed eye stents under evaluation are smaller than eye stents used today.

But rather than the chance to make the tiny part easily, arguably it is the chance for a material change that brings the most striking advantage to the stents for glaucoma surgery. Machining in metal is the only practical way to produce the stents today with the necessary fine precision and to the relatively low quantities needed. Microscale 3D printing on the BMF platform opens the way to making the parts from polymer instead. The stents can therefore be made to dissolve in the body. Today, glaucoma sufferers need one surgery to implant the metal stent, another to remove it. In the future, the second surgery might be eliminated.

Micro 3D Printing for Tiny Connectors: The Cool Parts Show S3E4

Microscale AM offers an alternative to micromolding and micromachining. On this episode of The Cool Parts Show, 3D printed electrical connectors are our smallest cool part yet. WATCH

Related Content

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read More3D Printing Startup to Deliver Thousands of Custom Hearing Aids Over Next Five Years

Starting with a pilot program in Jordan, nonprofit 3DP4ME is developing workflows to 3D print hearing aid earmolds and prosthetics near the people who need them.

Read More3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read MoreRead Next

Where 3D Printing Makes Sense for Micro Medical Devices

A contract manufacturer uses stereolithography to produce high-quality medical devices on a micro-scale for prototyping and end use.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More