Are Crystals the Key to 3D Printing with Silicon Carbide?

If SiC was easier and cheaper to apply, we would find many more uses for this hard, lightweight ceramic. Researchers have found a promising additive manufacturing approach, with crystal growth as the bonding mechanism.

Silicon carbide (SiC) is a hard, lightweight, thermal-shock-resistant ceramic material used for parts as diverse as car brake discs and bulletproof body armor, and it could find use in many more applications if only it was more accessible. Today, making components from this material involves molding at high heat and pressure. Mold tooling is needed within a molding process capable of 2,000 to 2,700˚C and 1,000 to 2,000 atmospheres. But could those requirements and this intensity of processing be avoided? Could additive manufacturing (AM) make this material easier to work with?

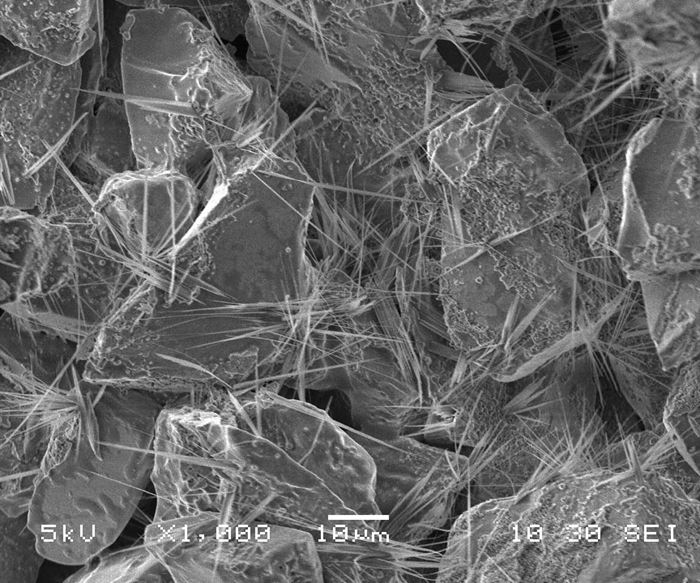

Maybe yes. University of North Carolina Charlotte (UNCC) professor Tony Schmitz and associate professor Ahmed El-Ghannam are leading a research project that has found a potentially promising new 3D printing method involving a new mechanism for binding this material. A new mechanism is needed because the established approaches to additive don’t work well with silicon carbide. The inert material can’t be melted in a focused-energy process and it resists fusing through a process involving sintering. But Drs. Schmitz and El-Ghannam’s work shows that crystals of silicon dioxide (SiO2) create a strong bond between silicon carbide grains, potentially pointing the way toward making parts with this material without mold tooling or a high-power molding press.

The material resulting from this process would not be pure SiC. Rather, it would be a composite of SiC and the SiO2 binder. In terms of strength, hardness or other useful properties, it might be something less than molded SiC, but close.

The researchers’ approach involves chemically activating the surfaces of silicon carbide grains. A solution containing sodium hydroxide serves to break the bond between silicon and carbon at the surface. The free silicon is attracted to oxygen in the air. This attraction is enough that heating the green part to just 600˚C (that is, heating the part after it has been printed or otherwise formed) is enough to energize the silicon sufficiently to find oxygen and form SiO2 crystals connecting adjacent SiC grains. That temperature, 600˚C, is low enough to be attained using an inexpensive benchtop furnace.

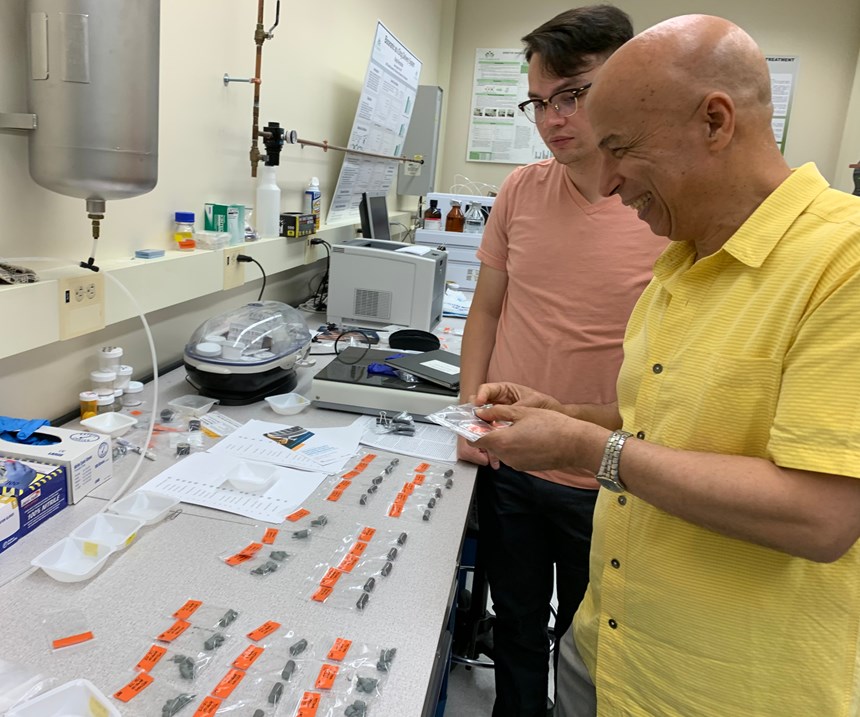

This effect has been demonstrated so far in discs and cylinders of SiC, ranging in size from 10 to 25 mm in diameter and 1 to 20 mm tall, that were soaked in the solution and heated. The next step will be to apply this effect in 3D printing to demonstrate the possibilities it offers for precise geometric control. During my recent visit to UNCC, I saw the 3D printer that the mechanical engineering department had successfully adapted for this purpose (see the third photo in the slideshow above). Dr. El-Ghannam points out that potential for geometric control in this process might be precise indeed—better than other 3D printing processes. This is because both sintering and heat treating, steps routinely associated with metal additive manufacturing, can change the form or dimensions of the part. By contrast, crystal growth is a binding mechanism between grains that leaves the positions of the grains where they are. With this method of bonding the material, there would be no appreciable warping or shrinkage.

Related Content

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreHow Additive Manufacturing Is Transforming EVs and Transportation: AM Radio #23

As 3D printing is adopted into the electric vehicle (EV) market, it is not just vehicles that are being reshaped. In this episode of the AM Radio podcast, we discuss additive manufacturing and the future of transportation.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreXJet Produces First Entirely Ceramic Piston for Chaos Ultracar

Company says no other technology could achieve the accuracy and complexity required to create Spyros Panopoulos Automotive’s lightweight ceramic design.

Read MoreRead Next

Printing End-Use Parts from High-Performance Ceramics

The lithography-based ceramic manufacturing (LCM) process allows the cost-effective production of ceramic parts even for a batch size of one.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More