September/October 2020 Issue

September 2020

Digital Edition

Features

Featured articles from the September/October 2020 issue of Additive Manufacturing

DMLS or Polyjet? A Hands-On Comparison to Produce Prototype Mold Inserts

The development phase of creating injection molded parts and inserts often requires the production of small-quantity prototypes. This moldmaker compared two different AM technologies to produce prototype mold inserts made from tool steel and polypropylene photopolymer.

Read More

Casting Goes Digital with Sand 3D Printing, Nondestructive Testing

Tooling & Equipment International (TEI) used to make tooling for castings. Now, it casts prototype parts in a digital workflow using 3D printed sand molds in combination with simulation software, CT scanning and X-ray technology.

Read More

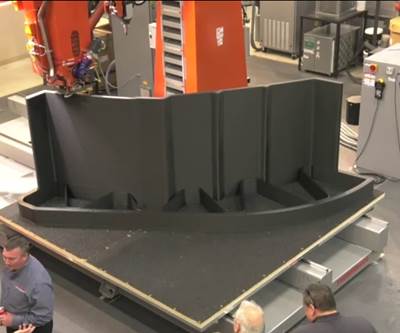

CGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

Read More

Reinforced Polymer 3D Printing, Adjustable on the Fly

With Continuous Kinetic Mixing (CKM), 3DFortify sees expanded possibilities for printing polymer composites reinforced with fibers, ceramics and even metal flake in any concentration needed.

Read More

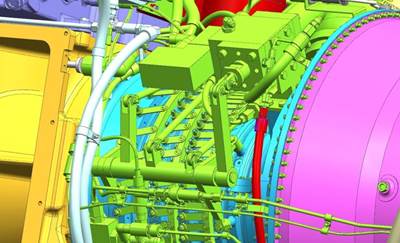

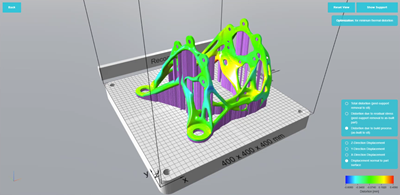

Topology Optimization Delivers Nonintuitive Design Features for Legacy Part (Includes Video)

Refurbishing a legacy turbine engine for energy efficiency provided the opportunity to demonstrate topology optimization in concert with metal 3D printing. The design for this torque arm comes from computer simulation insight refined with a human touch.

Read More

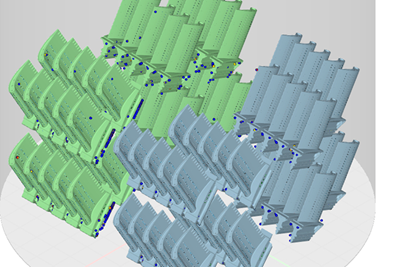

A Three-Piece Toolset to Minimize Metal Additive Build Failures (Includes Video)

Three separate software tools from Siemens attempt to control some of the most challenging variables within metal AM: build orientation, distortion and deposition paths. Part of software video series.

Read More

For Additive Manufacturing, Software Is as Important as the 3D Printer

AM is the process that both requires and realizes the possibilities of manufacturing software. Recently posted articles cover software tools for additive — each article with a companion video.

Read More

Bespoke Laser Cladding Nozzles Made Possible with Powder Bed Fusion

Additive manufacturing is advancing laser cladding. With the addition of a powder bed fusion 3D printer, American Cladding Technologies can now print custom cladding nozzles to meet the precise requirements of each job.

Read More

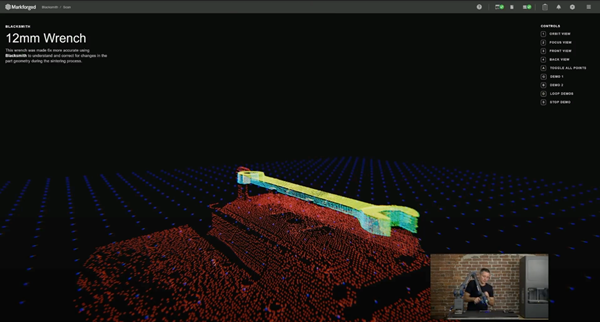

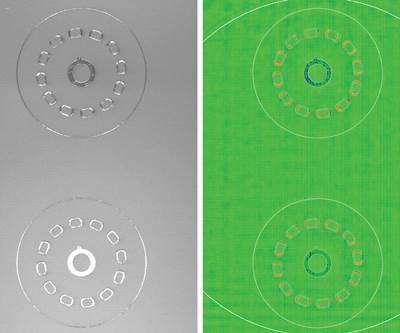

By Mapping Layer Height, Velo3D Shows Where Part Is Distorting (Includes Video)

Height measurement reveals what layers and what part features are potential problem areas in the metal additive manufacturing build. Watch the video to see how software provides insights from layer height data.

Read More

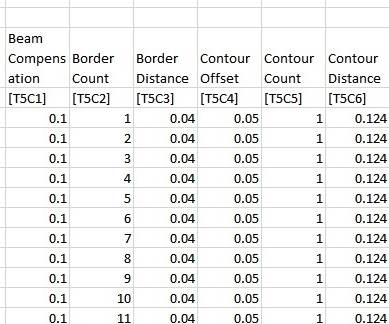

Your Metal AM Process Development Tool? A Spreadsheet (Includes Video)

Spreadsheet integration with Renishaw software allows for fast programming of metal additive manufacturing test builds. Watch video for demonstration of defining many laser parameter combinations for use in a single test.

Read More