September/October 2019 Issue

September 2019

Digital Edition

Features

Featured articles from the September/October 2019 issue of Additive Manufacturing

Are Emissions from 3D Printing Hazardous to Your Health?

And if so, what can you do about it? NIOSH researchers share the organization’s approach to eliminate, avoid and reduce operator contact with volatile organic compounds (VOCs) and ultrafine particles from fused filament fabrication (FFF) 3D printers.

Read More

As 3D Printing for Production Becomes Practical, the Attention in Materials Shifts to Practical Concerns

Recent posts relate to ensuring sufficient materials supply for production, certifying processes for AM materials, and even whether the properties of polymer AM include the ability to hold a screw.

Read More

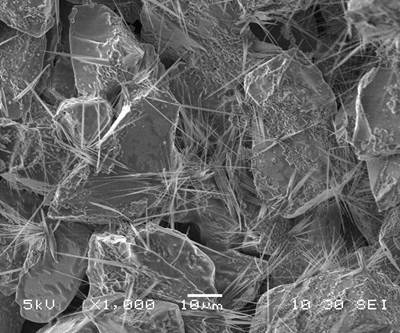

Are Crystals the Key to 3D Printing with Silicon Carbide?

If SiC was easier and cheaper to apply, we would find many more uses for this hard, lightweight ceramic. Researchers have found a promising additive manufacturing approach, with crystal growth as the bonding mechanism.

Read More

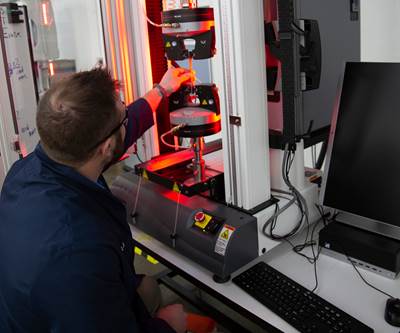

Interlayer Laser Peening Shows Promise for 3D Printed Implants and Beyond

Research at the University of Nebraska-Lincoln illustrates how applying secondary processes between 3D-printed layers can have a ripple effect on part properties. Dr. Michael Sealy explains the potential for medical implants using Optomec’s LENS platform.

Read More

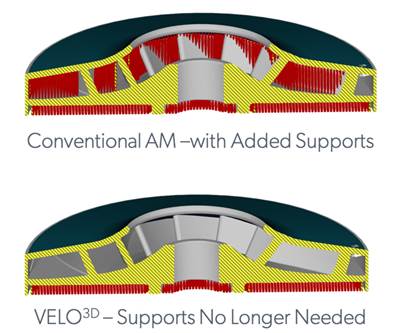

Velo3D: Avoiding Support Structures Means Metal AM Can Be a Solution for Direct Part Replacement

Because of the extent of the redesign they might call for, support structures can be an impediment to AM adoption. Reducing the need for support structures increases the viability of 3D printing for current parts.

Read More

Ultem, PEEK or PEKK? Choosing Between High-Temperature Plastics

How do you choose between these high-performance materials? A conversation with Arkema and Plural AM sheds light on 3D printing with these polymers.

Read More

Jabil’s Additive Materials Innovation Center: First Look

Additive Manufacturing Media was the first press to tour the Chaska, Minnesota, facility originally intended to be a clandestine additive manufacturing (AM) materials lab. What this capacity means for Jabil and 3D printing users.

Read More

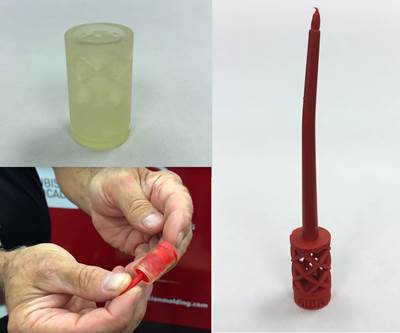

Injection Molding with the Geometric Complexity of 3D Printing

The Freeform Injection Molding (FIM) process from Addifab allows for injection molding resins to be processed into shapes not otherwise possible.

Read More