Machine Shop Turns to Additive for In-House Safety Covers and More

After purchasing a 3D printer to solve a safety issue, turning shop Swiss Automation has found many more applications for the additive manufacturing technology on its shop floor.

“When you look at the numbers and see that one in three injuries are being caused by the same thing, you know you have to do something about that,” says Vanessa Malo-Kurzinksi, vice president of Swiss Automation. Recognizing several years ago that too many of its machinists were getting bruised and cut from bumping against boring bars and other sharp tools inside its lathes, the company was prompted to look for a simple way to cover these tools and protect its employees. After failing to find a ready-made solution that it could purchase, and after rejecting the expense of building covers via injection molding or on its own turning centers, the shop turned to additive manufacturing.

Fused filament fabrication (FFF) enabled the company to make exactly the solution it needed, quickly and at a reasonable cost. Using a relatively inexpensive desktop 3D printer, Swiss Automation was able to design and produce customized tool covers, reducing injuries and improving the overall safety of its employees. But beyond these benefits, Swiss Automation is finding that the 3D printer can also solve many other simple problems on the shop floor.

Safety—In Numbers

As a large turning shop operating more than 130 lathes, Swiss Automation recognizes the importance of building and investing in its workforce, including their safety. Founded in 1965 by Ken Malo, Vanessa’s father, Swiss Automation has evolved from a one-man shop with six cam-operated lathes to an enterprise with nearly 225 employees spread between its main Barrington, Illinois, location and a second facility in nearby Cary. Today, the company’s primary focus is production parts ranging to 2.75 inches in diameter, commonly brass and stainless steel components for hydraulics and medical devices made on its Swiss-type CNC lathes.

Swiss Automation has been able to sustain its growth over the years in part because of its investment in recruiting, training and cultivating its workforce. The company conducts outreach and supports manufacturing programs at local schools, and it maintains a paid apprenticeship program that pairs new employees with veteran mentors. Many of its successful machinists and operators today originally came to the company with no prior manufacturing experience.

Building a large bank of talent has been a necessity for the company, but a bigger workforce also means the potential for more workplace accidents and injuries. Recognizing that safety was an area needing attention, the company in late 2013 created a safety committee headed by Malo-Kurzinksi and made up of administrators, shipping personnel, inspection technicians, operators and machinists to examine safety problems and propose solutions.

Almost immediately, the company’s HR manager came forward with a safety concern: Roughly 30 percent of Swiss Automation’s OSHA reportable injuries were related to employees bumping into cutting tools on the lathe turrets. These cutting tool injuries, most common amongst newer, less-experienced staff members, ranged in severity from bruises to lacerations requiring sutures, and sometimes resulted in infection. Affected employees had to take time off or serve light duty until they recovered. With three to four of these injuries happening each year on average, the problem was driving up the company’s DART—days away, restricted or transferred—OSHA rate. These accidents often also resulted in damage to the delicate cutting tools the shop uses to make its tiny parts.

The solution was obvious from the beginning: Cover the tools. The committee’s challenge was to find how to do that simply and cost-effectively. As in other turning shops, many of Swiss Automation’s machinists were already in the habit of throwing an oil rag over top of the cutting tools when working in the machines, but the thin fabric did little to protect them when a hand or wrench inevitably slipped.

After searching and failing to find a better option on the market, the committee realized that it would have to figure out how to cover the cutting tools itself. Several ideas were tried and rejected. Cork stuck on the end of the tools worked but wasn’t durable, and its neutral color made it easy to forget to remove. Colored leather was more visible, but it didn’t stay in place.

Turning to Additive

Finally, Malo-Kurzinski asked Marc Moran, the shop’s foreman, and Matt Savers, then-programmer, to determine how Swiss Automation could best make its own tool covers. After brainstorming designs and investigating the costs of injection molding or turning covers on its own lathes, Moran brought up the idea of 3D printing. The technology would allow the company to make its own tool covers without tying up a production lathe. Plus, he saw additional benefits to bringing additive technology into the shop.

“3D printing is something you hear about a lot these days,” Moran says. “We thought, ‘If this is where things are heading, we want to be on top of it.’” Purchasing its own 3D printer would be a way for Swiss Automation to make tool covers in-house while allowing employees to learn about additive technology. Savers began to investigate the market, looking for a printer that (1) offered a decent work envelope, (2) would be dependable and (3) would enable the shop to make tool covers out of durable ABS plastic. It turned out an expensive machine wasn’t needed.

The shop selected a LulzBot Taz 5, a desktop FFF 3D printer with a build envelope measuring 11.7 by 10.8 by 9.8 inches. Questions about dependability were addressed by the machine’s favorable Amazon user reviews (a resource not typically part of the shop’s equipment purchasing decisions). The company worked with LulzBot manufacturer Aleph Objects of Loveland, Colorado, to produce a successful tool cover prototype before finally purchasing the system in March of 2014. By April, the printer was installed at the Barrington facility in an out-of-the-way nook under a staircase, with an old laptop hooked up to run it.

In theory, operating the 3D printer is relatively simple. Components are designed in a CAD program (Swiss Automation uses SolidWorks), and then the programmer drags and drops the resulting STL file into Slic3r, a freeware program recommended by LulzBot that cuts the 3D model into layers. The slicing software generates the G code, which is then conveyed to the machine via host software or on an SD card. At the printer, the user sets the layer thickness, temperature and speed parameters and begins the build. As Swiss Automation discovered, it’s setting those parameters that can make or break a build.

“In the beginning we had issues with delamination which made the product weaker and more prone to break,” says Malo-Kurzinksi. “We had to learn how to balance the printer’s speed with the thickness of the walls.”

“It was a lot of trial and error at first,” recounts Daren Johnson, operator machinist. “Matt had to figure out how to run the printer at the right speeds with the right amount of heat so the filament wouldn’t overheat and coil.”

After a period of prototyping and experimentation, Savers was able to turn out durable ABS tool covers on the LulzBot and production took off. When Savers left the company mid-2015, machinist Shawn Johnson stepped up into the programmer role, which by that time also included running the 3D printer. Johnson began his own experimentation, learning from online resources such as the LulzBot website but also relying heavily on trial and error to get the prints just right. Now, the shop has the capability to reliably print a functional tool cover from ABS whenever needed.

Each tool cover is designed for a specific machine and tool (the corresponding model number is printed directly into the side), with sizes ranging from 0.75 to 1.125 inches in diameter and 2.5 to 3.5 inches long. Larger covers that fit over two tools at once are as large as 3 inches long and 1.25 inches wide. The basic tool cover design can be modified easily and inexpensively to fit any lathe or toolholder as needed.

The tool covers are printed in a vertical orientation and one at a time because of the constraints of the printer’s envelope. Johnson typically runs the printer at a 40 mm/sec. perimeter speed (how fast the printer extrudes filament to outline each layer or island) and 60 mm/sec. infill speed (how fast it fills in each perimeter with a solid layer or pattern). At these rates, a standard tool cover takes about 1 hour to complete and uses about $1 worth of material. The printer can run faster than this—its top print speed is 200 mm/sec.—but Johnson says running it slower results in better part quality.

“I’m not running a big batch of production parts so I’m not out for speed,” he says. “I want good parts.” Every material is different, he adds, so while Swiss Automation now has a good grasp on how to print in ABS, Johnson hopes to expand the company’s knowledge in the future by building a library of the best speeds and other parameters for working with additional materials.

Layer height for ABS parts is set to a relatively thin 0.3 mm to help maintain precision, he says. The printer’s tolerances—ranging from 0.05 to 0.35 mm (0.002 to 0.020 inch) in the X and Y axes—produce tool covers that are accurate enough to fit snugly on the toolholders with no magnets or other attachment mechanisms. This accuracy plus the fact that aesthetics are not critical means that the tool covers are ready to go right off the build plate, with no finishing or postprocessing required.

Making the Sales Pitch

Learning how to make the tool covers on the printer was a challenge, but it turned out to be only part of the solution to the cutting tool injury problem. For the covers to be effective, the team had to make sure that machinists would remember—and want—to use them. Team members’ ideas included engraving the covers with employee names or adding personalized stickers.

In the end, it came down to color. The team has found that tool covers printed in bright yellow, green and red are more attractive and appealing to use. They are also more visible, so machinists remember to remove them from the lathes

before starting up. The option of color allows for personalization and has even increased usage, as some machinists have requested covers in their own favorite color after seeing them around the shop.

Malo-Kurzinski estimates that about 70 percent of Swiss Automation’s machinists now use the tool covers regularly. Since implementing them in July 2014, Swiss Automation has had no cutting tool injuries on machines where the covers were installed. In fact, three different employees have reported bumping into the tool covers, but thanks to the barrier, none of the three sustained injuries. The couple of cutting tool injuries that have occurred in that time frame have been on machines where employees were not using the covers. A next step will be to bring that number down to zero.

“Our goal is that by the end of this year, everyone will be using the tool covers all of the time,” she says.

Swiss Automation is also testing the market for selling its tool covers to other turning shops. It has launched coveryourtools.com (based on the slogan imprinted into the side of each cover) and started bringing the tool covers to trade shows—including PMTS earlier this year—to get the word out. Depending on demand, the company is considering making the covers on its lathes or possibly purchasing another printer to replace or work alongside the LulzBot Taz 5 to increase production.

The Ripple Effect

But even if the tool covers never take off as a sellable product, Malo-Kurzinski and Moran agree that the 3D printer has more than paid for itself in reduced injuries and saved time, not to mention the value it has added to Swiss Automation’s shop floor. A walk through the Barrington facility is almost an Easter egg hunt for the brightly colored, 3D-printed objects around every corner, demonstrating just how integral the LulzBot has become to daily operations.

In addition to other safety products, like bumpers to cover sharp protrusions on the bar loaders, Swiss Automation is using its 3D printer to make components that it previously would have purchased at greater expense from suppliers—things like grippers for its manipulators, which can range from $250 to $750 per pair. With the printer, the price is much less, only about $6 per set in material costs.

The shop is also able to make tools and equipment that better suit its operations. For example, the standard steel parts catchers that come inside most of its lathes were too short to accommodate some of the shop’s longer parts. Rather than purchasing an alternative or welding one in-house, Swiss Automation can now print longer catchers with shallower sides to better hold these parts. Besides being cheaper and faster to acquire, the 3D-printed catchers have another advantage: The ABS plastic is more shock-absorbent than steel, helping to protect the surface finish of parts that fall into it.

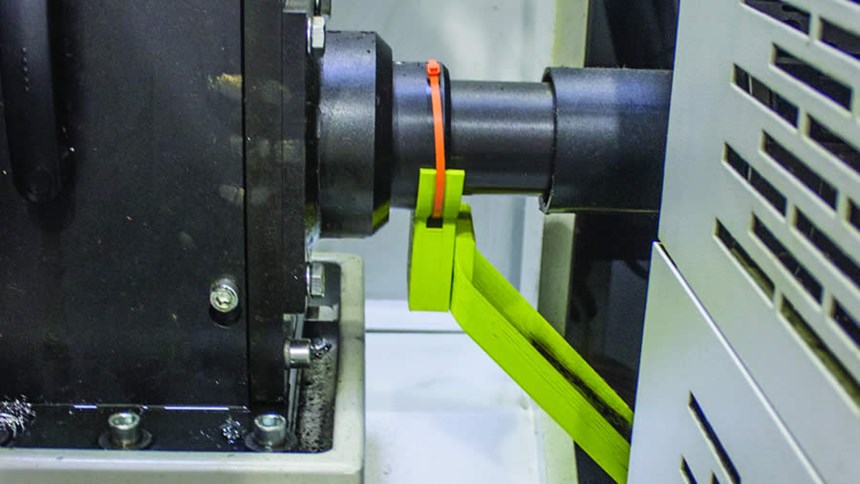

Employees have been eager to bring their own ideas to Johnson (and Savers before him) to be made on the printer. For instance, when a machinist noticed that one of the lathes was dripping coolant onto the shop floor, he helped to design a 3D-printed chute (affixed to the machine with a zip tie) to funnel the liquid into the tank instead of onto the floor. The practical benefits of objects like this are enhanced by the level of ownership and pride the employees take in these solutions.

“I like designing and prototyping a part, and then seeing it work in real life,” says Johnson. “With the 3D printer, you get to work with the machinists and change the design based on their feedback.” The machinists, in turn, get a component that precisely fits their needs.

“Like with any new machine, you have to mess with it and learn about how it works,” says Moran of the 3D printer. “But then you start seeing more and more applications for it.” Even with the learning curve, the knowledge gained combined with the practical uses the shop has found for its 3D printer have made the purchase worthwhile. Whether it is building tool covers, parts baskets or a one-off prototype, the printer at Swiss Automation rarely sits idle for long.

Related Content

What is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read MoreRead Next

Why Your Machine Shop Will Have a 3D Printer

In the future, we’re likely to take it for granted that small machining businesses routinely use 3D printing as a complement to their machine tools. The 3D printer can do work that frees up the more valuable machines.

Read MoreAgility Through 3D Printing

Additive manufacturing capability has helped this shop stay flexible, in both the prototyping and moldmaking parts of its business.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)