AM Molds Improve Quality of Injection-Molded Plastic Parts

A case study illustrates how additively manufactured metal molds could improve the quality of molded pressure reduction valves, reducing scrap along with speeding cooling.

Share

Read Next

Conformal cooling lines produced via additive manufacturing are useful in reducing cooling times for injection molding, but that’s not their only benefit. Because cooling time makes up only a portion of cycle time, other factors—such as the quality of components and number of rejected parts—are equally, if not more important. As illustrated in a recent case study from GF Machining Solutions, conformal cooling lines can play a role here as well.

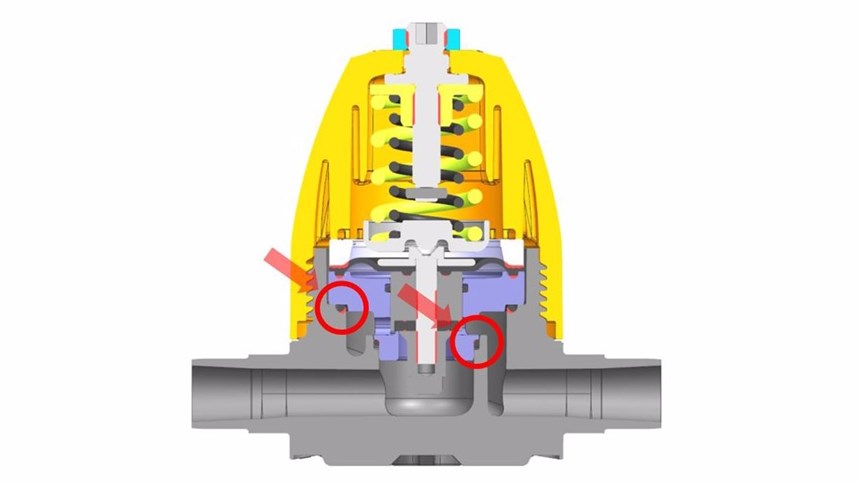

The production of the GF PRV-DN50 pressure reduction valve has benefited from the integration of conformal cooling lines in its mold. The valve, produced by GF Piping Solutions in Seewis, Switzerland, is made in a variety of materials and intended for use in the global chemical industry.

A critical quality characteristic for this part is the flatness of the weld lines near the seal seats (see Figure 2). Valve bodies with weld lines deeper than 0.01 mm and deviations larger than 0.2 mm between the two extreme values in a flatness measurement at 40 points are considered rejects. Shrinkage in the cylindrical valve body, in particular, can cause unevenness in the upper seat seal.

Variotherm Temperature Control

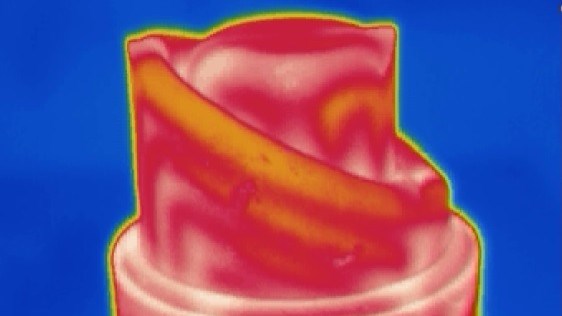

It is possible to better control the quality of the part through variotherm, or dynamic, mold temperature management. This strategy requires that the mold surface temperature react as quickly and homogeneously as possible to changes in the temperature of coolant flowing through the mold.

Both the cavity and core mold inserts for the valve have geometric elements that prevent conventional manufacturing technology from producing a close-contour channel geometry. Previous approaches—including producing the cavity from thermally conductive Ampcoloy and assembling the core from three conventionally produced, separate components—were unable to ensure the necessary reaction speed of the molding inserts in response to a temperature change in the coolant. Therefore, manufacturing the mold inserts additively was considered as a potential solution.

Simulating Success

GF Machining Solutions and Innovation Plasturgie Composites (IPC, Bellignat, France) worked in close cooperation to verify the design of a close-contour channel system using a series of simulations, iteratively optimizing it based on the results.

The flow volumes and speeds were assessed via fluid simulation to determine the length and diameter of the channels. Mechanical simulation helped to calculate the lifetime of the mold cores under a load spectrum typical for the injection molding tool, to determine whether the diameter, shape and position of the channel system would be able to withstand the expected loads long term. Finally, thermal simulation was used to determine whether the desired temperature distribution on the surface of the mold, as well as its reaction speed, would be sufficient for temperature management. The optimized design of the core insert can be seen in Figure 3.

On the cavity side, the material for the mold insert was changed from Ampcoloy to corrosion-resistant steel powder CX, providing hardness of 51 HRC.

To reduce manufacturing cost, a hybrid production method was chosen. The geometrically simple lower part of the both mold inserts was designed to be machined conventionally on a mill-turn center, while the complex upper part was intended to be made additively.

The mold inserts were processed with high-speed milling (performed on a Mikron Mill S 400 U) and die-sinking EDM (with an AgieCharmilles Form 200). Then, they were fitted to the existing injection mold. After setup, the simulated results were reproduced.

Improved Flow, Reduced Rejects

In testing, the flow volume of the additively manufactured core insert increased by a factor of 3.75 over the conventionally manufactured original. At the same time, the insert maintained a more homogeneous surface temperature which stabilized in less than 20 percent of the time taken by the original. The weld lines in both seal seats, as well as the shrinkage in the cylindrical valve body, were almost entirely eliminated.

According to GF Machining Solutions, the redesigned molds resulted in an almost complete elimination of reject parts, and cycle times reduced by 10 to 15 percent.

Related Content

How Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)