AM at Jabil: From 3D Printing Materials to Distributed Manufacturing

One of the largest manufacturers in the world has made a significant investment in 3D printing — both as a user and an advancer of this technology. Our original reporting dives into the what and why of additive manufacturing at Jabil.

Why is Jabil interested in additive manufacturing (AM)? The global manufacturing solutions provider serving OEMs in various industries already does injection molding on thousands of presses and metalworking on thousands of machine tools. And therein lies the answer to the question: Jabil leaders say they expect AM not just to become a fully accepted production process, but also to transform production. Therefore, the company is investing to advance AM to this point today. By expanding its 3D printing capacity and certifying 3D printing within established quality standards, the company aims to be able to produce with additive manufacturing just as routinely and effectively as does with conventional processes.

To understand production AM at Jabil, we visited various sites within the company and spoke with Jabil team members involved with additive. Watch our video above for an overview, and find links to our original reporting below, starting with our interview with Vice President of 3D Printing and Digital Manufacturing John Dulchinos.

Jabil’s Additive Manufacturing Vision

There is a chicken-and-egg problem inhibiting AM from realizing its promise for production, Dulchinos says. To realize the full benefit of AM, parts must be designed for this process. However, OEMs are reluctant to commit the part design to AM without assurance of reliable and sufficient capacity in the supply chain. Jabil hopes to break this stalemate by qualifying and scaling up its own AM capacity to become this dependable AM production source.

The likely result will be a different mode of production, he says. Parts will be produced not in batches but in families, and they will be produced as needed for assembly without shipping or storage.

READ MORE

Solving the 3D Printing Materials Challenge

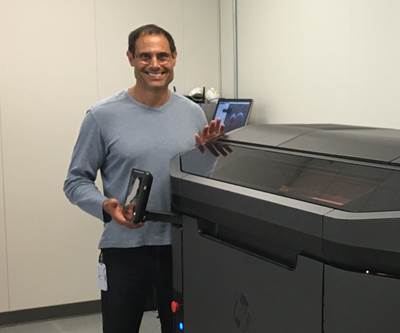

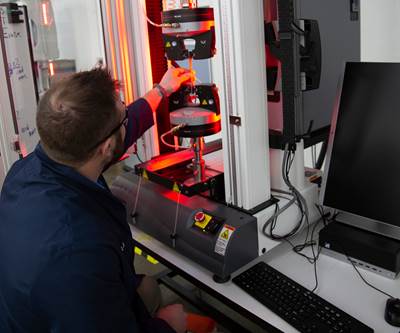

Additive Manufacturing Media was the first press to tour Jabil’s Additive Materials Innovation Center in Chaska, Minnesota. This 46,000-square-foot facility includes equipment for developing, testing and manufacturing materials for polymer 3D printing.

The purpose of this Center is partly to ensure that the right mix and volume of polymer 3D printing materials will be available as Jabil moves into AM production at scale. But another part of its purpose has to do with confidence. The facility focuses not just on creating new 3D printing materials, but on proving them out so that they print reliably on known machines with specified parameters. The long-term promise of that confidence is distributed manufacturing on a global scale, and the ability to manufacture where and when needed, in just the quantities required.

READ MORE

Production 3D Printing in Practice

With additive manufacturing, making parts and assembling parts no longer need to be separate. Jabil’s assembly facility in Auburn Hills, Michigan, has traditionally received all its components from machine shops and molders located elsewhere. That will change. 3D printing capacity at this site will allow parts to be printed just-in-time for production without entering into inventory.

AM technology is ready for this mode of production now. To apply AM and to realize this promise, Jabil is characterizing production 3D printing resources within the ISO quality system that defines the rest of the work of this plant.

READ MORE

Related Content

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Read MoreConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreRead Next

How to Implement Additive Manufacturing Across a Global Company: 5 Lessons

With more than 100 facilities and about 200,000 employees worldwide, Flex has a steep challenge in bringing 3D printing into its operations. Five things the company is learning.

Read More10 Questions About Additive Manufacturing for Production with Jabil’s John Dulchinos

“We’re in this for the long haul,” he says. Here are the challenges facing 3D printing for production, and here are the ways those challenges will be overcome.

Read MoreJabil’s Additive Materials Innovation Center: First Look

Additive Manufacturing Media was the first press to tour the Chaska, Minnesota, facility originally intended to be a clandestine additive manufacturing (AM) materials lab. What this capacity means for Jabil and 3D printing users.

Read More

.jpg;width=70;height=70;mode=crop)