Airbus Partition Built in Pieces for Weight Savings

The large component was successfully produced within a limited build envelope thanks to connection features designed into the pieces. Advances in powder-bed build size will permit greater efficiency in producing parts such as these.

Weight savings is one of the promises of additive manufacturing. A powder-bed process such as direct metal laser sintering (DMLS) makes it practical to generate a metal part that is neither solid nor hollow, but instead comprised of a mesh or lattice structure for the combination of light weight and high strength. In theory, the part could be engineered to have only the mass needed for the application and not a gram more. Still, the relatively small build size of powder-bed additive machines works against this important promise, because it is obviously big parts that offer the best opportunities for saving weight. The smaller parts able to be built within the envelopes of these machines often don’t offer much weight to save.

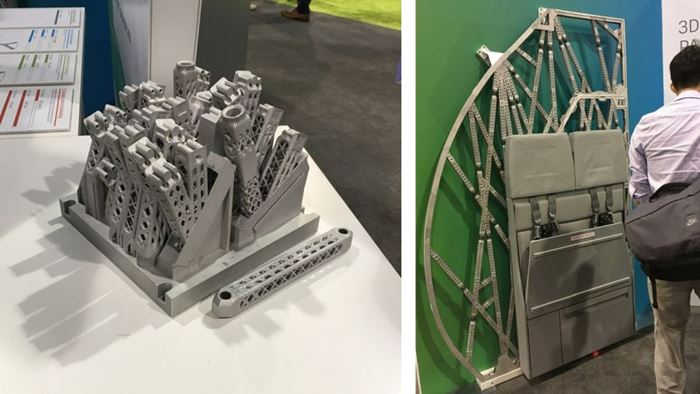

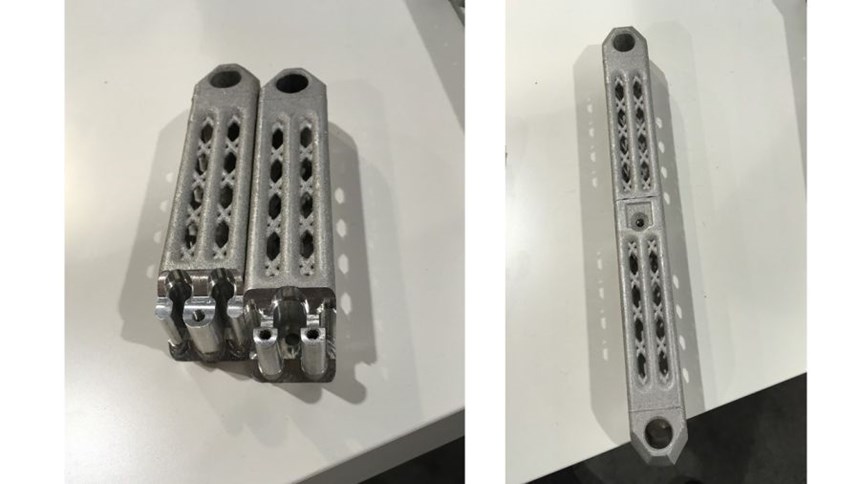

Aircraft maker Airbus recently demonstrated a workaround for this challenge with a large interior component it reengineered for weight savings. The frame of the partition within the A320 aircraft that separates the passenger compartment from the galley was reconceived for AM, with its solid aluminum alloy members replaced by lattice-like structures. The change reduced the weight of the partition by 45 percent. However, the nearly 7-foot-tall frame is vastly bigger than the envelopes of the EOS M290, EOS M400 and Concept Laser M2 machines used to additively produce it…so the big part was grown in pieces.

Airbus Innovation Manager Bastian Schäfer says the redesign of this partition frame is part of a company initiative to reduce greenhouse gas emissions on current aircraft. Lighter weight on an aircraft means less fuel for a given trip, reducing emissions. I spoke with him about this at a recent Autodesk event. (The partition was redesigned using Autodesk software.)

He says part of what made this design successful is the fact that the weight savings came without any component connected to this partition having to be changed. The new partition fits all of the same interfaces as the old one. Regulatory bodies must review changes to aircraft designs, he notes, so it sped approval significantly that only this part needed recertification and not a much larger assembly. The lightweight partition is now approved to fly, meaning airlines can replace the partitions on their A320s with this version. He guesses partitions like this might be in full production within two years, but the idea is still being refined. While the use of additive for this component is straightforward and ready for production, there are still some challenges in the secondary steps.

“The difficulty is the connections between the 3D-printed pieces,” he says. “After hot isostatic pressing, we measure each piece to find the connection surface, then CNC mill the feature to bring it to tolerance.” This step is performed one piece at a time today. Efficiency in full production will require this operation to be somehow systematized or automated.

A bigger powder-bed machine would help as well, he says. Just an incremental increase in build size over that of the machine used to make these pieces so far would have a meaningful impact on productivity. By permitting larger pieces, the larger size would reduce the number of connections that have to be machined. It would also allow more of the partition to be made in a single build. Right now, seven additive builds are needed to make all the pieces in one partition. Getting that number of builds smaller would deliver a processing time improvement. In short, the redesign of this partition almost certainly isn’t finished, says Schäfer. Airbus is investigating the use of a larger powder-bed machine with an eye toward these types of savings.

Related Content

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More