Additive Manufacturing at IMTS: 5 Things to Look For

Production, deposition, inspection and hybrid are among the areas where advances are apparent this year.

Share

Additive manufacturing continues to expand its presence at IMTS. This year, the Additive Manufacturing Pavilion nearly tripled in size, hosting 56 exhibitors compared to 21 at the last show. Two events at the show also focus on AM, the Additive Manufacturing Conference by Gardner Business Media September 11-12 and the AppliedAM: Where Additive Minds Meet symposium by EOS North America September 12.

What developments in AM can attendees look for at the show this year? Here are several:

1. Systemization Advances Production

Once associated with single-piece runs or small batches, 3D-printing-style processes are now capable of repetitive production and are being aimed at higher-quantity applications. To achieve that production, additive machines are increasingly being integrated into systems that combine 3D printing with preprocessing and postprocessing operations.

Example: AddUp’s FlexCare is a containerized production system for metal AM. It houses the company’s FormUp350 metal 3D printer along with the powder-changing, evacuation and recycling equipment needed to safely operate the AM process plus an integrated washing machine to clean build plates and parts.

2. Deposition Has Its Day

As one of the older methods for metal 3D printing, laser metal deposition is sometimes perceived—or more accurately misperceived—as a crude or simple approach to metal AM. Systems for building metal parts via deposition have now advanced in sophistication to the point that they are winning fresh attention for the possibilities they bring to part production and design.

Example: Formalloy’s X-series laser metal deposition system offers closed-loop control, variable-wavelength lasers and coordinated powder feeders for printing bi-metallic features or metal gradients. Scanning technology on this machine monitors build quality and accuracy in real time to allow for auto-correcting errors.

3. Polymers Do the Work of Metal

By providing a way to make parts from high-strength or reinforced polymers without the need for the tooling that is typical of plastics manufacturing, AM increases the range of applications in which plastic or polymer composite can be used cost-effectively as the material of choice.

Example: The Model One from Impossible Objects achieves ongoing production of polymer composite parts. The machine’s approach employs sheets of carbon fiber, Kevlar or fiberglass, fusing them with materials such as Nylon 12 or PEEK to build strong, lightweight parts.

4. Inspection’s Importance Increases

For AM to deliver not just functional parts but repetitive production, inspection technology has to validate those parts inside and out.

Example: Zeiss helps AM users apply optical 3D scanners, CT scanners, X-ray microscopes and coordinate measuring machines to detect not only 3D-printing defects but also downstream processing problems. The company’s CT scanners allow for inspection of the interior structures of parts made through AM.

5. Added Possibilities on Machine Tools

Hybrid manufacturing, meaning the ability to perform additive operations on the same CNC machine tool that also does metalcutting, continues to advance. The range of machine tool suppliers now offering hybrid solutions is a major part of the reason why additive at IMTS extends even well beyond the Additive Manufacturing Pavilion. Established hybrid providers continue to extend their offerings.

Example: The VC-500A/5X AM HWD multitasking machine from Mazak incorporates what it calls “hot wire” laser deposition technology to bring additive capability along with welding to a five-axis machining center. An arc torch melts metal wire onto a base or workpiece to generate coatings, 3D parts or near-net-shape part features for production or repair of items such as as impellers, turbine blades, and tool and die components.

Related Content

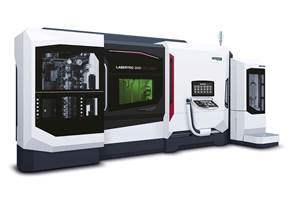

DMG MORI’s Hybrid 3D Printer Offers 5-Axis Simultaneous Machining

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Read MoreHybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Read MoreCNC Engineering Integrates 3D Printing Solutions With CNC Machine Tools

CNC Engineering and Meltio have collaborated to design a solution that combines the power and reliability of FANUC CNC with cutting edge additive manufacturing technology.

Read MoreAM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More