Additive Manufactured Components Reach Jupiter

The Juno spacecraft includes titanium waveguide brackets made through AM.

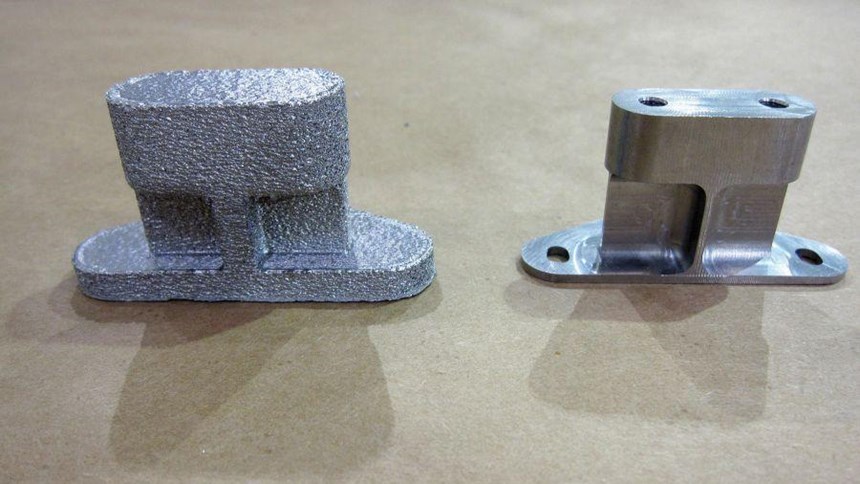

(From 2016) The Juno spacecraft that arrived in orbit around Jupiter on July 4 has now carried additive manufacturing farther than it has ever gone before. Among the spacecraft’s parts are components produced through electron beam melting, including the waveguide bracket seen in the photo sequence above.

Lockheed Martin Space Systems manufactured this part when it had just begun to use EBM. Read about the company’s work in AM in this article and this one.

Related Content

-

8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

-

Can Additive Manufacturing Compete With Conventional Manufacturing on Cost?

When it can, says Evolve, the design advantages of AM find their way in. The company is beginning to ship its high-speed AM system for polymer part production.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.