3D-Printed Prototypes Become the Parts with Carbon Fiber Filled Filament

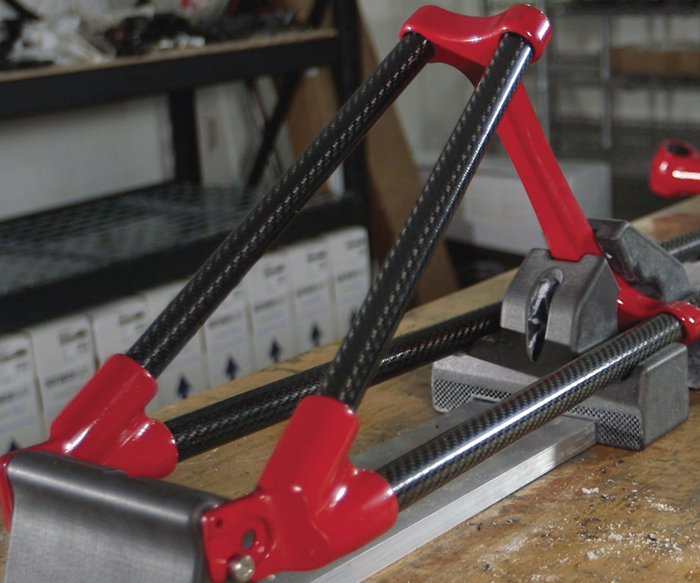

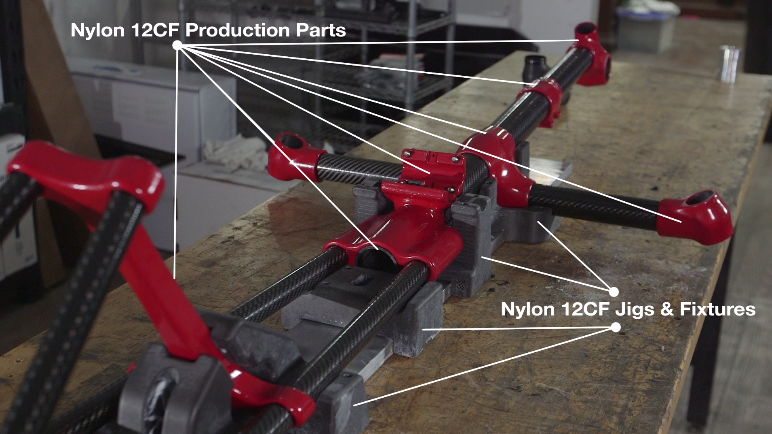

Utah Trikes, a retailer and manufacturer of trikes and quads, has grown its custom business using FDM Nylon 12CF to produce end-use composite parts that formerly would have required moldmaking.

3D-printed prototypes are commonly used to check the geometry, fit and even functionality of a component. But what if the 3D-printed prototype could actually be the production part?

For Utah Trikes, a provider of recumbent trikes and quad bikes, moving seamlessly from prototype to production part has become a reality, driven by the personalized nature of the products it sells.

"Almost everything we do involves some level of customization," says Ashley Guy, founder of the company. Utah Trikes sells a full range of ready-made trikes, quads and parts, but also offers customized components ranging from accessory mounts all the way to trikes and quads created specifically for the rider. “A lot of what we’re doing is finding the right ways to combine the trikes we make or sell with other options that are out there,” Guy says. Popular modifications include custom mounts, adaptations for riders with disabilities and even motors.

The company was founded 12 years ago with a storefront in Payson, Utah, and it wasn’t long before the company got into customizing soon after. Tailoring bikes to customers began with sandblasting equipment and powder coating ovens for custom paint jobs, but soon expanded into welding, tube bending, machining and other fabrication technologies. Today, the Utah Trikes shop contains about 20 different metalworking machines, and the prototyping and building of custom parts is a significant portion of its business.

The Prototyping Bottleneck

In the past, those custom parts were commonly produced via carbon fiber layup. Developing a custom part involved prototyping the part, machining a mold from aluminum and then completing the layup to produce the test part. The process was slow and expensive for the small quantities Utah Trikes deals with. A “big production run” might be only 100 parts, Guy says, while it’s more common for the shop to be making unique, one-off parts or just a dozen or so units.

To help speed the development process and reduce cost, Guy explains that the shop previously manufactured prototype parts or molds in pieces as they were being designed. “We would kind of work simultaneously to design the parts of a product and fabricate it using our metalworking ‘gut senses’ to get things done faster,” he says. Even so, the need to create a mold was still the main bottleneck in developing a new part.

“Because the cost of making the mold was so high, even if it wasn’t perfect, we would deal with it,” Guy says, explaining that the shop would try to keep changes to a minimum and work with the initial mold rather than building a new one whenever possible.

Utah Trikes purchased its first 3D printers about two years ago to help deal with this prototyping problem. After installing a Stratasys, Inc.Fortus 450mc, provided by Phoenix Analysis, Design & Testing (PADT), Utah Trikes was able to produce functional prototypes much more quickly and soon began printing the molds themselves out of Ultem 1010, dramatically shortening the development cycle for custom products. The 3D printer also proved useful in the production of custom jigs and fixtures used for assembly.

A Material Shift

But it wasn't until a new material became available that Guy considered 3D printing actual production parts. In spring of 2017, Stratasys released FDM Nylon 12CF, a carbon-fiber filled filament for use in the company's Fortus 450mc 3D printers. Chopped carbon fibers evenly distributed throughout the filament increase the stiffness of the polymer, giving it a higher ultimate strength. The material is 35 percent carbon fiber by weight, and according to Stratasys offers the highest stiffness-to-weight ratio of any of its FDM materials.

“We design a part, we print a part and then we test a part…. We’re bypassing the mold completely, and just making the part directly.”

That strength showed through in the prototypes Utah Trikes was printing. Where before Nylon 12 was too flexible and Ultem 1010 cracked, the carbon fiber-filled prototypes proved durable enough that they could be installed on the actual trike or quad and taken for a test ride. The process for manufacturing custom parts is now totally different as a result.

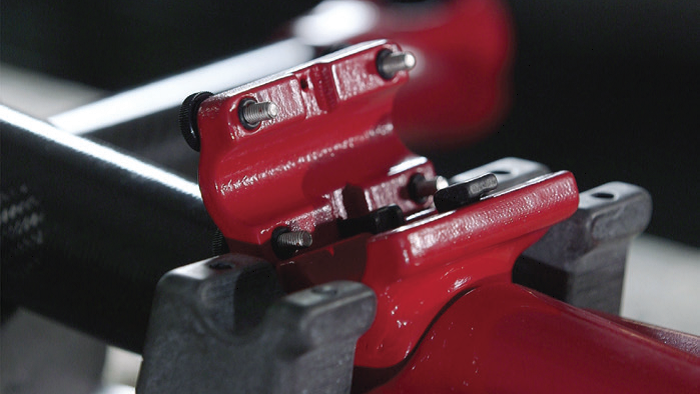

“We’re using material that we can 3D print that’s strong enough that we don’t even need to make a mold anymore,” Guy says. “We design a part, we print a part and then we test a part. If we need to make changes, then we just make changes and print a new one. We’re bypassing the mold completely, and just making the part directly.” That change could save the company between $5,000 and $10,000 on a given mold, and accelerate the production timeline for a custom part from months down to just weeks or even days.

The combination of strength, impact resistance and finishing ability made Nylon 12CF a good fit for producing trike and quad parts, says Guy. “We’ve gotten pretty good at designing parts for printing so that we don’t need to do post machining,” he says. Instead, most parts simply go through a tumbling process with a blend of media. When they come out, the part is smooth and the print lines are gone. “It actually ends up looking like a molded carbon fiber part,” he says. After tumbling, the parts receive a clear coat; sometimes a spray paint is applied as well.

New Applications, Changing Priorities

The combination of 3D printing technology and the carbon-fiber filled material has increased the amount of custom work Utah Trikes is able to produce. It has also changed the type of work it can do, opening possibilities for greater creativity.

“The first thing we used to consider before 3D printing was, ‘How are we going to make this part?’” Guy says. “We were very conscious of the fact that we’re starting out with a rectangular piece of aluminum, for example, and the design would tend to be highly influenced by the material and how we were going to machine it.” Now Utah Trikes can design a part strictly for its function, including geometries that would not be machinable. 3D printing enables the company to make virtually any part it needs, even single parts, at much lower cost.

“We have a viable product now that otherwise simply just would not exist.”

One result is that Utah Trikes has been able to complete projects that would not have been possible previously. Several years before installing its first 3D printer, the company had started to develop a full-suspension, four-wheel-drive pedal quad. However, it wouldn’t have been possible to accurately machine the correct angles in the suspension without spending tens of thousands of dollars on jigs, and so the project was abandoned. Using the Fortus 450mc and FDM Nylon 12CF material, Utah Trikes was able to produce the parts necessary to finish the quad.

“We took all those parts we had designed and modified them a little bit for 3D printing,” Guy says. “We were able to print them out and they were the exactly the right angles and the right geometries that we needed right off the bat. We have a viable product now that otherwise simply just would not exist.”

Related Content

Rekkie AR Ski Goggles Made Possible With 3D Printing: The Cool Parts Show #53

When the electronics enclosure key to these AR goggles proved difficult to mold, 3D printing allowed the inventors to keep the complexity — while also making improvements for assembly and user experience.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreRead Next

Carbon-Filled Thermoplastic 3D Printing Material Replaces Handmade Metal Parts

Handmade metal part required replacement three times a month, with delivery times of a month or more.

Read MoreOrion Gets a Lift from Electro-Static Dissipative (ESD) Material

NASA’s Orion spacecraft will include parts 3D-printed from electro-static dissipative Antero 800NA from Stratasys. Developing this material was an exercise in working within constraints.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)