3D-Printed Molds Accelerate Substitute-Ventilator Validation

Fortify’s 3D printing and injection molding expertise saved Ventilator Project weeks and thousands of dollars as the nonprofit hurried to supply clinicians and hospitals at the start of the COVID-19 pandemic.

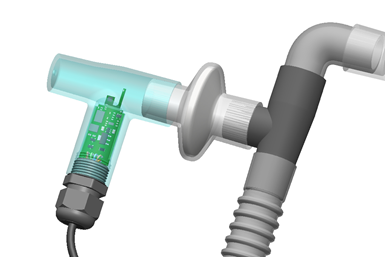

Ventilator Project, a Rhode Island-based nonprofit sourcing alternative ventilator solutions to meet clinician and hospital demand during the coronavirus pandemic, obtained thousands of donated sleep apnea machines (such as CPAP and BiPAP devices) to serve as supplementary equipment for hospitals. Once the organization sent these machines to doctors to establish a protocol for use, however, Ventilator Project received feedback that the machines needed a disconnect alarm. This critical feature would alert clinicians if airflow to the patient was interrupted at any point and establish these home-use machines as suitable ventilator substitutes for hospitals.

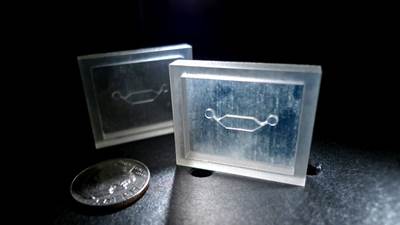

Ventilator Project designed a T-splitter component to house the alarm, but needed to create a prototype of the final device to test in an oxygen-rich environment to receive FDA approval. This became a materials problem: the nonprofit needed to conduct efficacy and safety validation testing on the part and end-use manufacturing material — in this case, polypropylene — before it could scale up production.

Injection Molding and 3D Printing Challenges

While 3D printing could have delivered a prototype to confirm the fit, form and basic function of the T-splitter, achieving FDA approval for a medical device requires the manufacturer to validate a test component made from the end-use material using the end-use manufacturing process. Although suppliers now offer polyproplyene as a 3D-printing material, Ventilator Project knew it would ultimately make the splitters via injection molding. Validating the design would therefore require an injection molded, polypropylene T-splitter, and obtaining the tooling could cause an especially sizable impact to the project’s cost and timeline. With the ongoing nature of the coronavirus pandemic making time a precious resource and the project’s minimal budget limiting its options, Ventilator Project could not proceed with traditional manufacturing methods.

To solve this issue, Ventilator Project partnered with Fortify, a digital manufacturing company based in Boston. Ventilator Project came to Fortify with two T-splitter designs that it wanted to test.

Lowering Costs with a 3D-Printed Injection Mold

Rather than design and build two full conventional molds, Fortify’s applications engineering team designed and 3D printed one mold tool with two sets of hand-loaded core inserts that were capable of producing two unique geometries from that mold. The molds were made on the company’s in-house Flux One 3D printer platform from its Digital Tooling resin through a combination of magnetics and digital light processing (DLP) 3D printing. The Flux One’s Digital Composite Manufacturing (DCM) technologies – Continuous Kinetic Mixing (CKM) for even mixing of resins and additives, and Fluxprint for magnetically aligning reinforcing fibers across each 3D-printed layer – resulted in greater control over the final geometries of the Digital Tooling-comprised inserts while increasing their durability.

The team’s ability to print the inserts simultaneously alongside the mold added no extra time to the build and only added an additional $30 to the cost.

Especially important in saving time and cost was the ability to 3D print threaded inserts. Threads are typically challenging to prototype due to long lead times — even an off-the-shelf insert can take one or two weeks to source, and several quotes for the custom thread Ventilator Project needed clocked in at six weeks. A threaded insert can also add an additional $1,000-$2,000 to the cost of the tool, depending on the complexity of the part ejection method. By contrast, Fortify’s 3D-printed threaded insert added minimal time and cost to the project.

The two-piece assembly of the inserts streamlined production by minimizing both the material needed to 3D print molds for each geometry and the required force for finished part ejection, reducing the required force enough that the team could remove finished parts by hand.

T-splitters made with the 3D-printed mold tooling met Ventilator Project’s requirements for fit, form and function while enabling validation testing using injection-molded polypropylene — all while saving thousands of dollars and weeks of lead time compared to traditional aluminum tooling.

In the end, where traditional aluminum tooling would have cost $4,000 and taken between three to six weeks of lead time, the 3D-printed molds produced by Fortify only cost $700 with a lead time of seven days. With these benefits, Ventilator Project was able to select one design with maximum confidence — partnering again with Fortify to run those inserts on the company’s in-house press.

Related Content

Micro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read MoreRead Next

Where 3D Printing Makes Sense for Micro Medical Devices

A contract manufacturer uses stereolithography to produce high-quality medical devices on a micro-scale for prototyping and end use.

Read MoreMagnetic 3D Printing with Fiber Reinforcement Fills Tooling Gap

Fortify’s Digital Composite Manufacturing (DCM) platform pairs high-performance resins with fiber reinforcement that can be controlled at the voxel level. The process promises a faster route to durable injection mold tooling.

Read MoreInjection Mold or 3D Print? How Resolution Medical Pivots Production

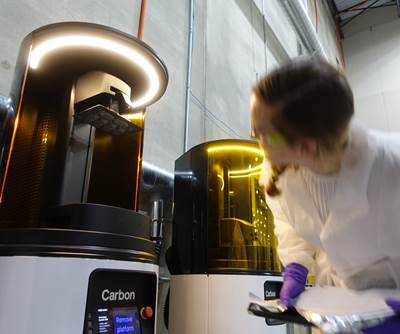

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read More