3D Print or Stock? A Model for Spare Parts

3D printing provides a way of manufacturing spare parts on demand, in situ. But is it always the best solution? A new model from a Duke University professor aims to help companies make these decisions.

Picture this scenario: A transformer blows out in a rural town. The utility provider needs to replace that transformer as soon as possible to restore service. Its local facility downloads the necessary part files from a central cloud server and sends them to an in-house 3D printer for production. The electrical service for the town should be up and running again soon, right?

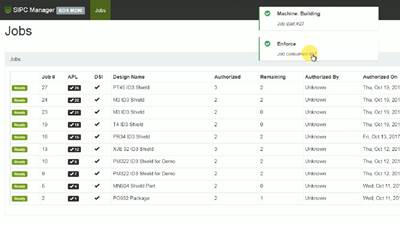

Is it more cost effective to print on demand, or keep spare parts in inventory? A new mathematical model will help companies decide.

But now imagine that the printer is already occupied, manufacturing parts for another power outage in a different location that won’t be completed for hours. Or maybe the components needed are large, and will take more than a day to print. Suddenly 3D printing these parts on demand may not be the best-case scenario. The local utility provider may even find that it can have the needed parts sourced and shipped from another facility before it can print them on site and complete the repair.

It’s scenarios like these that a new mathematical model for spare parts was designed to avoid. Created by Jeanette Song, an operations professor at Duke University’s Fuqua School of Business, this model is intended to help companies decide whether to keep spare parts on hand or print them only when needed.

“If the part is in stock, then you can satisfy that demand immediately,” Song says. “But if you don’t have any inventory, then every part has to wait at least for printing time and maybe other delays.” The key is deciding which parts will be needed immediately, and which can still meet the need cost effectively when they are printed on demand.

Breaking Down the Spare Parts Supply Chain

This model for procuring spare parts has its roots in a consulting project Song worked on for a utility provider entering a new international market. “This was a clean sheet; they did not have any operations there,” Song says. “In order to provide the equipment, they also had to lay out the supply of spare parts before deciding whether to go to that market.”

In that consulting project, Song focused on developing a high-level decision-making framework that the client could use to weigh various factors concerning which of its spare parts could be printed on demand and which should be held in inventory. This work provided a foundation for the more detailed mathematical model she then created with Yue Zhang, then-Ph.D. candidate at Duke and current assistant professor at Pennsylvania State University. Their research was recently published in the journal Management Science.

The Cost Factors

As Song described to me over the phone, the mathematical model centers on minimizing cost. It breaks down each of the procurement options into its various costs to determine the most effective way of supplying spare parts. For 3D printing on demand, that includes print time and cost per unit. For conventional parts to be stocked, it considers unit order cost and order lead time, as well as inventory holding cost. The model also takes into account a part’s likelihood to fail as well as “waiting cost,” or the cost of downtime while a given part is out of commission.

...a part that seldom breaks down or is simple enough to be printed in a few hours could be a good candidate for 3D printing on demand.

“Based on these parameters, we determine optimal stocking level to minimize the expected annual cost of managing inventory,” Song says. For a critical part with a short life span, that optimal stocking level might be a high number. But a part that seldom breaks down or is simple enough to be printed in a few hours could be a good candidate for 3D printing on demand.

Importantly, converting a part into its real or potential costs allows the model to be more or less process agnostic. It doesn’t matter whether the parts in question are typically machined, injection molded, or made through some other process, as long as that process can be quantified—and as long as the parts in question could be realistically 3D printed as a manufacturing option, one key assumption of this model.

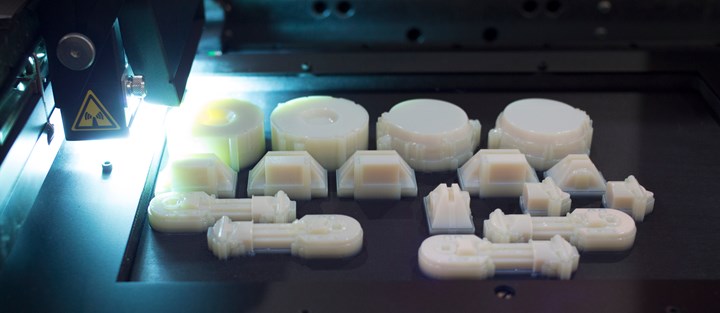

When spare parts are 3D printed on demand, companies still need to account for the time it takes to make them. Printing as needed may not always be the best solution, depending on part criticality, lifespan, print time and other factors.

3D Printing on Demand, Alongside Inventory

What Song has learned from this research is that most companies can benefit from a “hybrid” strategy for spare parts, a combination of 3D printing on demand and holding parts in inventory.

“We find that by using this hybrid approach of stocking some parts and printing others, the average cost savings is 5% relative to stocking everything,” Song says. “Maximum cost savings can be more than 40%.”

“...in the future when the technology advances, the unit costs will decrease and the savings should go up.”

Song expects that these numbers will shift and evolve over time. “We assume printing is more expensive than the traditional manufacturing unit cost,” she says, “but in the future when the technology advances, the unit costs will decrease and the savings should go up. The same is true as the print speed improves.”

The signaling methods for ordering spare parts are advancing, too, Song says. One project she is currently working on looks at using sensors in parts to enable “preventive printing.” When a sensor detects an imminent failure, it could indicate that it’s time to begin 3D printing a replacement, before the failure actually occurs — effectively reducing 3D printing’s lead time and expanding its effectiveness as an on-demand option for spares.

Related Content

Multimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreRead Next

Will Control Over Part Data Expand and Simplify AM Supply Chains?

Digital rights management for manufactured part files will enable OEMs to enforce manufacturing requirements at a distance, potentially providing an alternative to closely held relationships with suppliers of critical AM parts.

Read MoreOvercoming Obstacles to Bring AM into the Supply Chain

A conversation with Jabil’s John Dulchinos and HP’s Stephen Nigro illustrates some of the challenges in integrating additive manufacturing into a supply chain for production parts.

Read MoreMetal Additive Manufacturing Enables Spare Parts on Demand for Beverage Filling Plants

The ability to 3D print metal parts for the beverage filling industry as needed saves cost over conventional methods.

Read More

.jpg;width=70;height=70;mode=crop)