2014 JIMTOF Report: Machining Added to Additive

JIMTOF Report: Machining Added to Additive

Adding an additive manufacturing process to a machining center is interesting. Adding machining to an additive manufacturing machine is also interesting. Both developments show that additive and machining processes can supplement and complement one another.

Interest in additive manufacturing was high at JIMTOF 2014, as it has been at recent manufacturing technology shows, especially IMTS this past September in Chicago. The show in Japan (October 30-November 4) marked the appearance of several hybrid additive/machining combinations of both varieties mentioned above.

Mazak introduced its i400AM Integrex, which incorporates a rough and finish laser cladding capability as an extension of its multitasking concept. Separate laser heads are stored in the tool magazine for these operations. Likewise, DMG MORI displayed the Lasertec 65, which also features an integrated metal laser cladding system.

Having the additive process on board enables these machines to build up new surfaces or features such as ribs, tubular extensions, fan blades, flanges and more. It is possible to generate these new features in a material that is harder or lighter than the parent workpiece material. Once built up, these features can be milled in five axes, turned, contoured or otherwise machined before removing the part in a completely manufactured state (done-in-one).

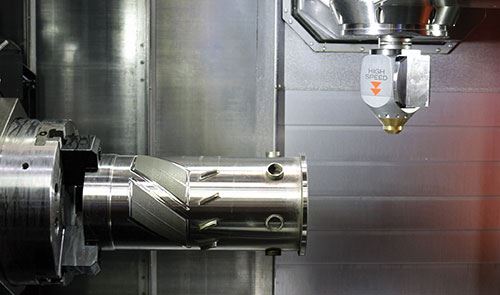

Two notable machines on display at the show demonstrated the value of adding a milling process to a laser sintering machine. The Matsuura Lumex Avance-25 integrates a fiber laser for sintering layers of metal powder with a high-speed milling process that contours a number of successive layers of sintered material. The milling leaves a surface that is smooth and accurate, requiring no subsequent finishing. The applications in focus at JIMTOF were mold components with complex internal cooling channels and deep, thin ribs. (This machine is marketed in the United States by MC Machinery Systems Inc.)

Sodick’s new metal 3D printer, the OPM250L, is a very similar hybrid laser sintering/high-speed milling machine. Reportedly, this machine can fabricate nine mold inserts in around 24 hours. The milling spindle has a top speed of 45,000 rpm.

Kitamura’s “reverse 3D printing” process deserves a note in this context as well. Although this capability does not include 3D printing, this builder has developed a directly integrated software program that interfaces between a scanner and the machine control. After scanning a 3D model with the scanner connected to the machine, the software converts the scanned points so the machine can cut the 3D object from solid material. This process is the focus of Kitamura’s XrossCut VMC, which uses two parallel X axes, one moving the spindle and one moving the table. While feeding one of these components in the plus direction and simultaneously feeding the other in the negative direction, cutting rates can exceed 9,000 ipm in aluminum, plastic or other soft materials.

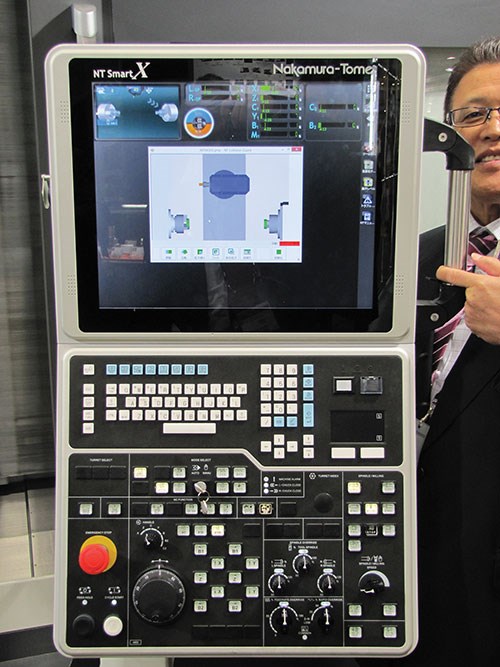

Of course, additive manufacturing was not the only highlight of this JIMTOF. Another significant trend noted was reshaping CNC units into large, flat panels with oversized high-definition display screens. New operating systems clearly copy the features and functions of the smartphone. Touchscreen navigation, customizable displays, hot-button shortcuts and easy networking make these CNCs appealing to the “connected” generation of young professionals in manufacturing.

In addition, JIMTOF confirmed other leading trends in machine tool design and capability. Multitasking capability continues to expand the operations it includes and the range of travel for integrated B, Y and other add-on axes. Likewise, few builders active in the milling arena do not offer five-axis capability now. Gear-making technology is also on the move, especially in highly productive skiving operations. Machines and cutting tools designed to handle titanium and other tough materials were also very much in evidence.

The next show in 2016 promises to fill expanded exhibit space at the Tokyo Big Sight conference and exhibition center, as well as offer its traditional emphasis on the advanced engineering that underlies Japan’s position as a leading source of manufacturing technology.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More