Lithoz, Himed Partner for Research on 3D-Printable Medical-Grade Bioceramics

This collaboration is designed to help grow the range of biocompatible materials suitable for a future that includes highly customized, patient-specific medical solutions that can be printed on demand.

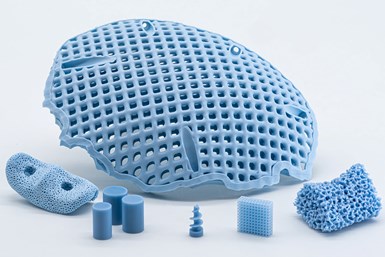

LithaBone HA 480 is a greatly improved human bone-like ceramic material which can be used to create distinctly blue complex parts. Photo Credit: Lithoz

Lithoz, a provider of ceramic 3D printing, and New York-based biomaterials manufacturer Himed have signed strategic research partnership agreement to further accelerate the development of medical-grade bioceramics. Focusing on implants using biocompatible calcium phosphates, the cooperation is designed to better meet the strongly increasing demand for innovative 3D-printable bioceramic feedstocks.

As part of the joint effort, Himed has acquired a Lithoz CeraFab S65 Medical Printer to explore novel integrations of its leading calcium phosphate biomaterials with Lithoz’s proprietary ceramic binder LithaBone HA 480.

After searching for a strategic partner in the United States to better access the potential of top-level surgery specialists there, this partnership forms the next logical step in the large-scale commercialization of this very specific 3D printing product. The partners say their collaboration will also help form an intercontinental pool of top researchers driving 3D-printable bioceramics to the next level. Partnering with Himed enables Lithoz to explore the potentials of other CaP phases within the sophisticated biomimetic forms its printers can make.

Thanks to its properties (such as excellent biocompatibility and osteoconductivity), the tricalcium phosphate or hydroxy apatite-based LithaBone medical ceramics have proven to be an attractive alternative to metals used in human surgery. Lithoz has also received numerous innovation study requests involving these bioceramics, as the precision and design flexibility of Lithoz LCM technology offers potential for innovation when it comes to lattice structures and porostities achieving the desired ideal level of osteoconductivity.

First-phase research will occur at Lithoz’s U.S. location in Troy, New York, this summer by a joint team of materials scientists. Himed will install a new Lithoz CeraFab S65 printer at their 25,000 ft.2 facility in Long Island early this fall, enabling the company to more rapidly experiment on-site and run analytical testing at its in-house laboratory.

The addition of a CeraFab S65 at Himed also broadens its R&D service offerings, adding rapid prototyping of different forms for clients who contract with Himed to conduct unique biomaterials research.

“Himed understands CaP optimization and how to scale it for a growing market. We’ve refined many calcium phosphates to strengthen their healing potential, but most of these were targeted toward surface coatings on traditionally manufactured titanium implants,” says Dana Barnard, Himed CEO. “Lithoz’s remarkable 3D printing technology allows a whole new direction for our products, in which we can use CaP to its greatest advantage — as a biomimetic material within the implant structure itself that can be replaced by a person’s own natural bone over time.”

Ultimately, both companies believe there is still much to discover about developing CaP materials to augment the performance of 3D-printed implantable forms. “This is definitely a big milestone for our partnership, and just a first starting point for a mutual beneficial collaboration for additive manufacturing of bone replacement,” says Dr. Johannes Homa, Lithoz CEO.

This strategic partnership represents a first step in growing the range of biocompatible materials suitable for a future that includes highly customized, patient-specific medical solutions that can be printed on demand. Over the last 30 years, calcium phosphates such as hydroxy apatite have gained widespread use in implantable devices, bone putties and grafting materials for their similarity to natural bone, and can aid the organic regrowth of hard tissue at the implantation site. Since 1991, Himed has collaborated with different medical implant manufacturers to develop and optimize various CaP powders and surface treatments for osseointegration. The partnership with Lithoz, however, enables new opportunities for Himed in the medical additive manufacturing market beyond bioactive surface treatments and postprocessing of implants.

- Learn more about Lithoz offering improved ceramic material for 3D-printed bone replacements. The company says the 3D printed, patient-specific parts made of hydroxyapatite are well suited for bone replacements in the medical and dental field.

- Read about Lithoz’s 3D printed ceramics serving as both bone graft and support. Bioceramics including tricalcium phosphate and zirconia have been used to replace and stabilize human bone in reconstructive surgeries. Now, 3D printing brings customization and new design opportunities to these medical devices.

Related Content

Ice 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)