3 Design Techniques for High Speed Extrusion 3D Printing

Simple design changes can reduce build time and improve part quality in this production-speed polymer AM process.

Editor’s note: “High Speed Extrusion” (HSE) is Essentium’s rapid deposition process for 3D printing polymer parts at production speeds. It is fused filament fabrication (FFF), but the speed means even the design considerations appropriate to FFF may not be sufficient for this process. Tom Mulholland describes the design considerations for HSE.

While there are many design tips and techniques for additive manufacturing (AM) to be found, such as tips for FFF, selective laser sintering (SLS) and stereolithography (SLA), these design tips are not always applicable to filament printing for High Speed Extrusion, which is a distinct process. Here we look at some design tips that will specifically help design for HSE to achieve faster print times without sacrificing quality or repeatability.

1. Avoid Sharp Corners

Cornering refers to the behavior of the toolhead as it goes around a corner, or changes direction in the XY plane. When it comes to design, the goal is to strategically adjust corners to allow the toolhead to maintain maximum speed.

When designing parts for HSE printing, there is no added time or expense to adding fillets (the rounding of corners). The rule of thumb is to make the fillet radius greater than or equal to 5 millimeters and using high resolution STL files during the design process. This allows the toolhead to move fast while maintaining geometric accuracy.

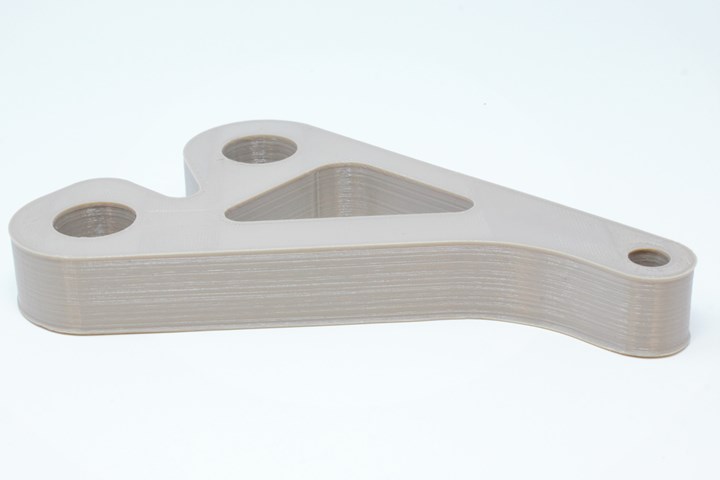

Rounded corners, such as those in this 3D printed bracket made of PEEK, help reduce build time in High Speed Extrusion.

The rationale is that any corners sharper than this require the printer to decelerate and then accelerate again, much like a car slowing down as it negotiates a corner. In a recent case, we saved 15% in print time by adding fillets to a fixture, which previously took 105 minutes to print. That’s impressive for one part, but imagine the time savings for hundreds or thousands of parts using this simple design technique.

By avoiding sharp corners in the part’s design, manufacturers not only reduce print time but also maintain a consistent print speed for the best quality parts.

2. Optimize Travel Movements

Travel movements are transitions between unconnected areas of material deposition. With HSE, travel movements can have a significant impact on print time.

3D printing processes like SLA have travel movements in the Z direction, but in filament printing and HSE, the travel movements are in the XY plane. This means travel movements take place on every layer, so the effect is multiplied by the number of layers in a similar cross-section.

This assembly fixture 3D printed in 5 hours via HSE would have required over 19 hours on a convention FFF printer.

The key to optimizing travel movements is to minimize the number of islands. Connecting otherwise disconnected areas ensures a more consistent extrusion rate, which will improve the quality, enable faster printing, and help avoid defects like stringing and blobbing.

3. Plan Toolpaths for Thin Walls

In planning the toolpath for High Speed Extrusion, engineering designers need to consider the way the printer will lay down the material.

When designing a thin wall, they should think about designing in multiples of the extrusion width, or the nozzle diameter that they’re going to use. For instance, on the Essentium platform, we generally use 0.4-mm nozzles and 0.8-mm nozzles, which means our toolpath width is going to be the same, 0.4 or 0.8 mm.

Avoiding uneven extrusion ensures the best quality and the best strength for part walls. The payback in terms of time savings is also significant — just by switching to wall dimensions in nozzle diameter multiples, we realized a 17% reduction in print speed on a recent chip tray printed through HSE.

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreRead Next

How Additive Manufacturing Is Expanding the Possibilities for Plastics

In terms of lead time, part size, quantity and inventory needs, the limitations on plastics are being overcome. We will see plastics doing more — the theme of several recent articles we’ve posted.

Read More6 Reasons to Use Plastic 3D Printing

Smaller batches and shorter lead times are just two of the benefits of 3D printing parts in plastic. Here are six reasons to choose polymer additive manufacturing (with examples).

Read MoreLinear Motor Platform Delivers Speed, Low Part Cost for Production AM

Essentium’s additive manufacturing machine based on semiconductor manufacturing has as much in common with precision machine tools as with other FFF 3D printers.

Read More