BASF Forward AM Develops Ceramic-Filled Resin for Zortrax Powerful Trio

Parts 3D printed with BASF Ultracur3D RG 3280 feature the characteristics of ceramics without the need to use special furnaces as the high content of ceramic particles ensures a true ceramic look.

Share

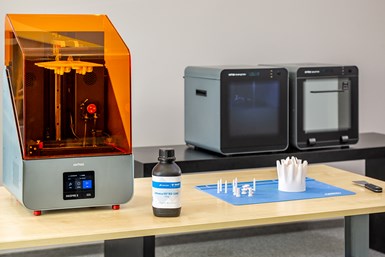

BASF Forward AM’s BASF Ultracur3D RG 3280 is a ceramic-filled resin for use with the Zortrax Powerful Trio, which is a comprehensive resin 3D printing and postprocessing system consisting of a Zortrax Inkspire 2 UV LCD 3D printer, Cleaning Station and Curing Station.

The company says the material is characterized by exceptional hardness, high stiffness and excellent resistance to temperatures, reaching up to 280L°C. It also has a stable particle dispersion and low viscosity that makes it easy to handle and print. The parts 3D printed on Zortrax Inkspire 2 and postprocessed on the Zortrax Cleaning Station and Zortrax Curing Station feature the characteristics of ceramics without the need to use special furnaces. The high content of ceramic particles ensures a true ceramic look of the target models.

As a further step in the long-term cooperation with BASF Forward AM, Zortrax is extending the broad range of photopolymers manufactured by BASF Forward AM which are compatible with the Zortrax Inkspire 2 UV LCD 3D printer. This latest material is a specialized resin with ceramic infill from the rigid line. Together with the Inkspire 2, it provides the ability to 3D print parts, which after the proper postprocessing with Zortrax Cleaning Station and Zortrax Curing Station acquire real ceramic-like properties, without the need to use costly furnaces.

Although the ceramic-filled resin from BASF Forward AM is a high-performance, specialized photopolymer with the unique properties, using it with Zortrax Powerful Trio is easy and convenient. It starts from preparing a model in Z-SUITE, where the users can find the ready, calibrated profile for BASF Ultracur3D RG 3280. The Inkspire 2 has been designed specifically to work with specialized filaments through a series of features, including a powerful, proprietary light engine. Moreover, during 3D printing, the users are also provided with suggestions for proper postprocessing. That enables the users to know the cleaning and curing times of their 3D prints. For parts made with Ultracur3D RG 3280, postprocessing in the Zortrax Cleaning Station takes only about 10 to 20 seconds, whereas in the Zortrax Curing Station it can take about 30 minutes for each side of the model.

“Despite the high content of ceramic particles, the resin has low viscosity and its sedimentation in the vat is limited, which translates into maximized ease of use and print quality,” says Artur Chendoszko, Zortrax resin technology leader.

Components 3D printed specifically with BASF Ultracur3D RG 3280 exhibit high stiffness and electrical nonconductivity. The resin is well suited for 3D printing objects requiring specific manufacturing processes, such as ceramic handling arms that move semiconductor wafers from one station to another or positioning and guide pins used in pressure welding. The resin is recommended for all manufacturing processes where the parts must provide highly desirable mechanical, electrical, thermal and chemical properties and function as a nonconductive, thermal insulation which doesn’t interfere with the welding process.

Due to characteristics such as resistance to corrosion, temperature, shape change, melting, stretching and distortion, ceramic materials are used for a wide range of applications in various industries, including aerospace, automotive, robotics, electronics, metallurgy, energy production and chemical industry.

“We're glad that our cooperation with BASF Forward AM is so fruitful,” says Natalia Jusiak, Zortrax head of marketing. “We are constantly expanding our product portfolio with materials for both FDM and UV LCD technologies. It is worth noting that Zortrax is the only 3D printer manufacturer on the market with such a broad portfolio of resins by BASF which are all compatible, tested and calibrated to work with the Zortrax Inkspire 2 printer.”

- Read more about Zortrax Full Metal Packages which are said to contain all the essentials for an easy start with metal 3D printing and include either BASF Ultrafuse 316L or BASF Ultrafuse 17-4 PH, which are metal-polymer filaments from BASF Forward AM.

- Check out #4 in our Top 10 Stories of 2022. With the launch of BASF Forward AM’s line of Ultrafuse filaments that carry metal powder mixed with thermoplastic binders, users of extrusion 3D printers meant for polymers can now produce their own green metal parts in-house.

Related Content

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read More3D Printing Brings New Possibilities for Manufacturing With Ceramics: AM Radio #27A

AM expands the opportunities for ceramics. On the AM Radio podcast, a discussion of various 3D printing processes making use of ceramic material, and various new applications for ceramics that are developing as a result.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More

.png;maxWidth=300;quality=90)